San Francisco-based Mantle reports an improvement in feature size and part strength. This should let its customers reduce EDM (electrical discharge machining) time, make more molds possible, and reduce sintering failures. Mantle’s machining-assisted paste binder jet process allows the firm to use harder materials with better finishes through binder jet. We’re fans of the firm that has specialized in the tooling market, using tool steels and catering to mold makers very specifically. By adopting a more focused go-to-market strategy, the company has specialized, learned deeply about its prospects, and shown growth through that approach.

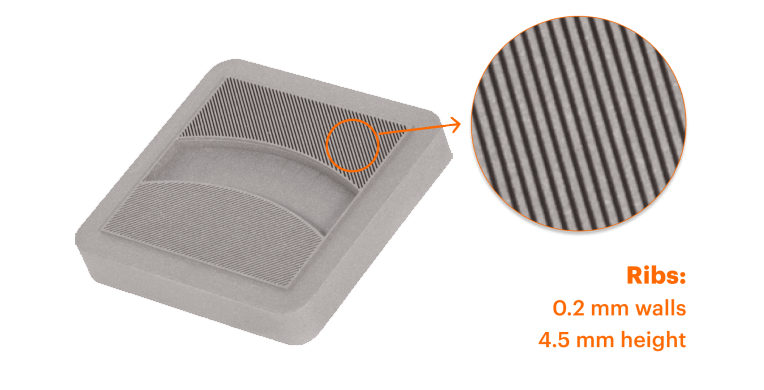

Now the company can print feature sizes as thin as 0.2mm. The strength of these features has improved. This is specifically important in binder jetting, where many parts and features often collapse or break when a part is in its fragile green state. The improvement applies to ribs, pins, and edges. The improvements are not a new machine, but rather a software update. The company’s Automated Toolmaking System software has received an update, which it calls Top Definition.

Ribs just 0.2 mm wide and 4.5 mm tall demonstrate Mantle’s ability to print ultra-fine features.

Top Definition changes the way the company prints,

“Instead of processing each layer individually, the new method prints a solid block of material at the top portion of the tool. This solid ‘top block’ is then machined from above in a top-down process, which encases and provides structural support for details much smaller than Mantle’s standard layer-by-layer print and machining can support.”

It’s great that Mantle’s architecture can support this and that the firm can offer software improvements like this to its installed base. At the same time, the company has disclosed that its bookings have doubled for the first half of the year when compared to a year earlier. One client, Conesys, has used multiple Mantle systems in making electrical connectors. Electrical connectors are a fast-growing segment in Additive. High-end connectors have a lot of SKUs, lead time challenges, and often want to make connectors close to customers. Generally, the firm believes its fortunes are being buoyed by reshoring and a renewed interest in manufacturing in the U.S., specifically for injection molding companies and mold makers.

Mantle’s three-step process produces high-precision metal parts with minimal post-processing.

Conesys Chief Information Officer, Mark Edwards, stated,

“For more than 10 years, I’ve been searching for a 3D printing technology robust enough for production molds. After validating Mantle’s technology and experiencing its unmatched precision, we’ve integrated multiple Mantle printers into our operations. We’re now reducing the time and cost associated with producing new tooling, allowing us to respond to our customers more quickly and bring new products to market. The adoption of Mantle’s new Top Definition capabilities will further enhance precision, driving even greater efficiency and throughput within Conesys’s toolroom.”