Beehive Industries was initially a more generalized service before focusing on manufacturing its own components. The path to get there was not an easy one; the company laid off around 18% of staff in July 2023, got a $12 million Air Force engine printing contract in October 2024, and in March 2025 got a contract through the System of Systems Consortium (SOSSEC), which manages rapid acquisition projects for the US Department of Defense, with the Air Force Life Cycle Management Center. Now the company is delving deeper into Unmanned Aerial Vehicle (UAV) propulsion by working on the 200 lbf Frenzy engine.

The company tested four different additively made engines, each iterated within six weeks. With a total of 20 hours of runtime, the company is optimistic that it will meet the requirements. After this, they want to work on altitude testing and hope to do flight testing in 2026. The engine models are small, measuring 12 to 20 cm, with 100 to 300 lbf of thrust and weighing around 6.8 to 16 kilos. This fills a gap in US engine production capacity and inventory, with larger, more complex engines widely available, but more compact engines being relatively rare. These kinds of engines could be used by missiles, new types of lighter cruise missiles, or many drones. If the US were to enter into a conflict, especially a protracted one, many thousands of these engines would be needed. Ukraine currently produces 5 million small drones per year and wants to produce around 300,000 long-distance drones per year as well. The US currently cannot match that level of production.

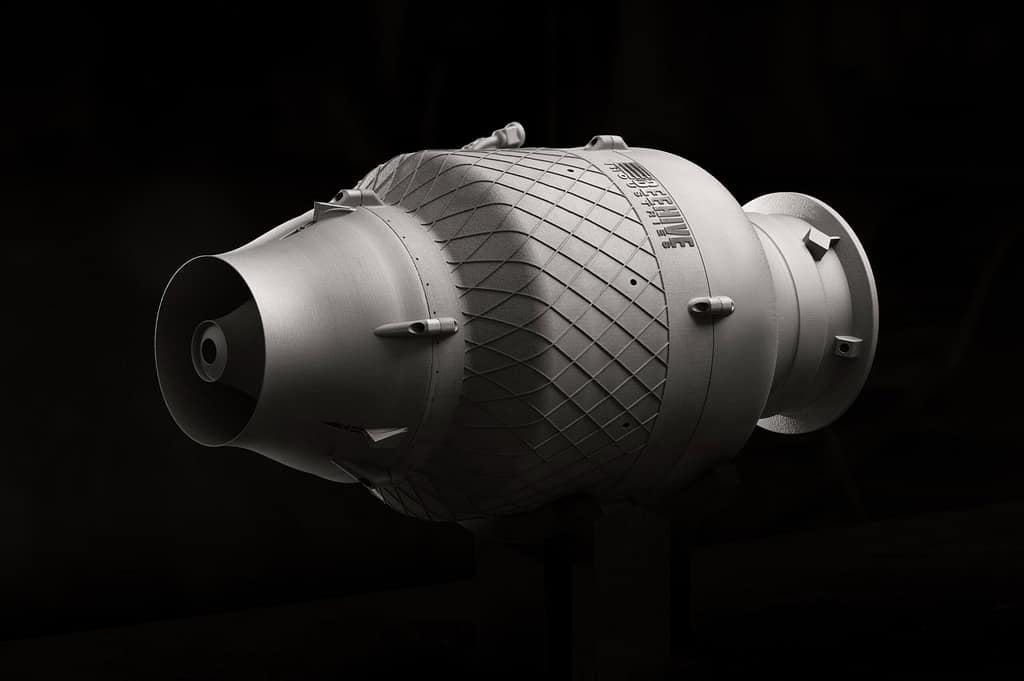

3D printed Frenzy engine. Image courtesy of Beehive Industries.

For the more complex, higher value drones the US has in mind, the challenge is even more pronounced. Commercial micro turbine manufacturers are also not located in the US. Beehive, therefore, could be looking at a particularly lucrative contract and business area if it continues its development. Small, cost-effective engines have been an area overlooked by Pratt and others. If Beehive can produce these things cost-effectively at scale, they will find themselves dealing with significant contracts.

Chief Product Officer. Gordie Follin stated,

“Beehive’s rapid advancement with the Frenzy engine family is a testament to our team’s expertise and the transformative potential of additive manufacturing.These test results exceed our expectations and reinforce our mission to provide the U.S. military with affordable, high-performance propulsion systems that can be deployed at scale. We’re proud to collaborate with UDRI and the U.S. Air Force to push the boundaries of aerospace innovation.”

3D printed engine. Image courtesy of Beehive Industries.

Their work with the University of Dayton Research Institute (UDRI) is sure to give them an edge as well. The research institute regularly works on Small Business Innovation Research (SBIR) and other innovative government projects in additive for engines and more. In addition to the Frenzy, the company is working on many more engines for larger craft with its Rampart engine. Ideally, of course, the company can quickly adapt a design to new specific needs or switch production between engine types and sizes. To a certain extent, it could be easier for them to make many more variants of an engine with the same R&D costs. Beehive is also aiming for affordability. Given the many legacy engines in use and the death of adequate engines for interceptor drones, and long-range, affordable bomber-type drones, there is a real need here. In fact, I would say that this lack of choice and availability is a critical weakness in the US arsenal. Similar engines could also be used for missiles and Patriot type applications, and could be used in their thousands if needed.

Beehive Industries is sitting on an absolute goldmine if they pull this off. They are active in a relatively new market with few reliable offerings. It’s US-based and uses GE 3D printers with an experienced team (often also Ex-GE). Given the many advantages that additive manufacturing offers in weight reduction, better flow, part consolidation, reduced assembly, better buy-to-fly, and more, there is a real opportunity here to make more margin and be cheaper for the end customer. With a more versatile design and manufacturing, the company could have a real edge. That could let it take on the large engine makers or indeed become one.