The most encouraging signs for the additive manufacturing (AM) industry these days are coming from the adopters: the companies that have made the technology a living reality by diligently developing processes that let the specific advantages of additive technologies speak for themselves. Gone are the days when all you had to be excited about were new machine launches, software updates, and exotic alloys.

And, at the same time as the ablest adopters are the ones in the spotlight, their success is certainly the industry’s own success, too. This is quite helpful for anyone trying to understand AM as a business. Despite the fact that there are always more companies to sift through, the increasingly real success exhibited by the companies leveraging AM means that it’s easier than it used to be to pick out which brands are the winners.

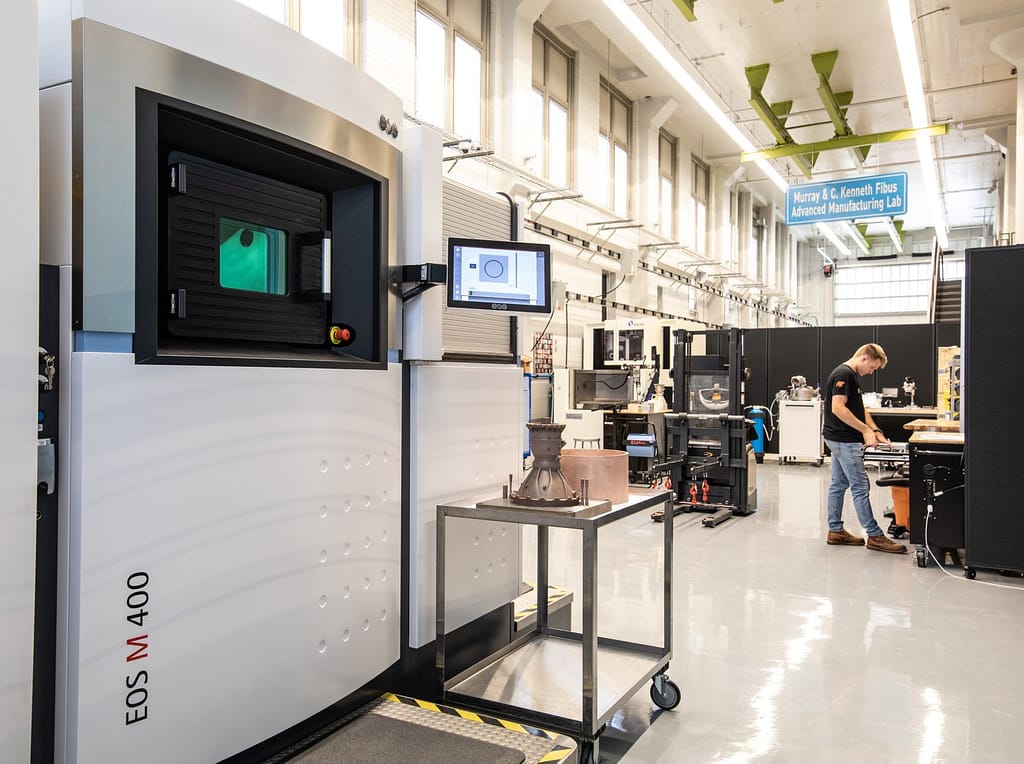

Rocket propulsion company Ursa Major’s Advanced Manufacturing Lab in Youngstown, Ohio, where its EOS laser powder bed fusion 3D printer produces rocket engine components on demand.

As I’ve written over, and over, and over again, Ursa Major is an AM adopter par excellence. Thus, it is especially helpful for anyone attempting to understand the AM industry to dig deeper into which companies Ursa Major selects as its partners.

As it turns out, that has also just gotten easier: a couple of months ago, the company announced that it had formed a consortium called the Alliance for the American Additive Manufacturing Ecosystem (AAAME). Some of the other founding members include software provider Dyndrite, laser manufacturer nLIGHT, and one of the AM industry’s pioneering original equipment manufacturers (OEMs), EOS.

Ursa Major and EOS have been strategic partners for years, a partnership that, early on, hinged on EOS’s early proficiencies with copper powder bed fusion (PBF). Greg Hayes, senior VP Global Additive Minds at EOS, explained to me the dual-sided nature of the partnership, with each company’s strengths adding to the strengths of the other:

“EOS would not be where it is today without the continuous pressure and demands from our customers,” Hayes asserted. “Our customer base is driving the industry forward, and I think that’s the best recipe for success in the context of applied technology. Everyone in an emerging technological field is looking for those customers that know how to push the limits of what’s possible, not just once but as a matter of routine.”

Ursa Major looks poised to push the limits of EOS technology even further in the near future. Not long before I interviewed Hayes, EOS announced that Ursa Major planned to buy three more M 450-4 FLX machines, made by the EOS brand AMCM, equipment that the launch specialist will use for hypersonic vehicle components:

In a statement to 3DPrint.com via email about the purchase, Nick Doucette, Ursa Major’s VP of Operations, said, “Ursa Major’s vision to scale production of affordable, high-performance hypersonic systems requires partners who have a track record of reliability and a history of technical excellence. EOS provides both of those through their decades of machine capabilities and their team at Additive Minds, whom we’ve had the privilege to partner with for many years.”

If there’s one connecting thread that unites EOS and Ursa Major, it’s the expertise with which each company navigates the constant back-and-forth between R&D and commercialization. Hayes views EOS’s capacity for meeting that challenge as one of its biggest selling points for a company like Ursa:

“What’s really awesome is that, as we partner with Ursa Major and work closely with their engineers, it allows them to take advantage of all the tools that are still in-development in the R&D centers at EOS. That’s one of the ways they’re able to keep pushing those limits,” Hayes said.

“That’s obviously not the path for every single company. There has to be an ‘easy’ button, so to speak, for a large swath of EOS customers. But a company like Ursa isn’t using an easy button: they’re applying an expert level of control to a very stable AM ecosystem that EOS has put together over a long period of time.”

While the Ursa path may not be the one for every company, it’s quite possible that as the AAAME evolves and expands, pushing AM’s limits may start to become a more accessible reality. Here’s how Ursa Major’s CEO, Dan Jablonsky, explained the impetus behind the AAAME in the press release announcing the consortium’s establishment:

“The United States cannot afford fragile supply chains subject to international economic disturbances or decade-long timelines to deliver critical national security systems. This Alliance brings together key players in the AM ecosystem to advance a more responsive and robust industrial base. It’s about aligning policy, innovation, and execution so our warfighters have what they need, when they need it.”

In practical terms, Hayes framed why Ursa Major is the logical fit to lead this effort that EOS, among others, has joined:

“I think Ursa Major is the right company at the right time to change how some of these engines are being produced, because they’re not burdened by being embedded within the status quo. They’re able to start fresh with the technology suited to the task at hand, they’ve got great IP in the hands of a great team of engineers. At least for the core products they’re focused on, that’s enabling them to make a bigger impact at a faster pace than the incumbent primes,” explained Hayes.

In that same way, EOS is the right partner at the right time for Ursa Major:

“The EOS brand — our machine capability and reliability — speaks for itself. I think that’s what Ursa Major was looking for, was a partner that could scale alongside their needs, which was reliable both technologically and as a business. They needed a partner that they could grow with as they scaled into larger and larger production, and a partner that was willing to roll up their sleeves and work with them until they understood exactly how our machines can optimize the parts they’re making.”

Going forward, another angle where the AAAME may be able to help Ursa Major, EOS, and the U.S. industrial base as a whole is by enabling more agile maneuvering between defense and commercial production. “Dual-use” is a severely overused term in this defense tech boom era, but it is still a real thing that matters, as a protocol that can enable surge production when national security calls for it.

Along those lines, Ursa Major’s commercial contracts, like one announced with the U.S. subsidiary of a Japanese space startup earlier this year, are just as important as Ursa’s defense contracts. Hayes pointed out that EOS’s diverse applications portfolio gives the company a leg up in this area, as well:

“The medical device industry and civilian aircraft industry both have to deal with very stringent regulatory bodies like the FDA and FAA, which parallels the defense sector,” said Hayes. “EOS is looking to stand up capabilities and work with organizations that are standing up capabilities that enable greater interchangeability between defense production work and commercial work.

“That’s something that a digital manufacturing technology like additive enables. But it’s just as important to have the organizational know-how and systems in place that support that type of activity: you have to have the contract manufacturing network and the supply chains that allow you to pivot as seamlessly as possible. Going forward, I think we’d look to embrace both sides equally and have a dual-use facility in place.”

Barely a week after I talked to Hayes, Ursa Major announced yet another major contract: $35 million from an undisclosed aerospace and defense company for Draper engines. I won’t be surprised if Ursa needs more printers soon.

Images courtesy of Ursa Major and EOS