We’re in the doldrums. And binder jet is more in the doldrums still. In the first article in this series, we looked at how Jedi Mind Tricks got us to misbelieve our own past and present. And so we sleepwalked into an illusion. Now we’ll look at the economics of jetting things and the chances the technology has to grow.

You may not know this, but the doldrums are an actual place, a band around the world. Caught between northern and southern trade winds, a moving area of winds cancelling each other out has trapped sailors for centuries. Becalmed sailing ships may languish there for weeks, making onward journeys less certain and worsening scurvy, disease, and starvation. This is but one reason why the Royal Navy and its rivals had to kidnap their citizens and force them into service as sailors. Travel today is notably safer and genteel, but aircraft still avoid the Inter-Tropical Convergence Zone. The crashing wind systems and sun cause lots of turbulence and powerful storms for aircraft, and have been contributing causes to the downing of planes.

We live in a world of turbulence. We live in a world where systems are colliding. In our world, the South is increasingly assertive as countries such as Brazil, South Africa, Indonesia, and India have their own agendas and ways of seeing the future. We live in a time of radical differences in worldview as well. From our lofty perches, we are mired in uncertainty as a chasm of an unknowable future opens before us. And this, this is bad news for everybody but excellent news for binder jet.

Where Is Binder Jet?

Binder jetting works when a binder is selectively jetted onto a spread-out, packed powder. This creates green parts that have to be cured, taken out of the build box, debound, and sintered. Binder jet uses inexpensive and abundant MIM (metal injection molding) powders and MIM industry expertise for sintering. Traditional problems are with conveyancing generally, green parts collapsing under their own weight, deposition errors, system reliability, spreading/coating, and packing. One issue is the difficulty in estimating shrinkage and supports in novel parts. Shrinkage changes as per geometry, wall thickness, and size, with variations occurring with new materials. This means that in a traditional service bureau or prototyping role, as well as some mass customization scenarios, binder jet has no role or only a limited role to play.

Binder chemistry is complex, jetting knowledge is compartmentalized and inaccessible, while researchers are fewer on the ground than with, let’s say, the laser. Print heads are available from a limited number of vendors, and they may lock down certain aspects of their technology or price them too high. Design for binder jet is not widely understood and is complex. Part size, for most players, is limited to around a paperclip in all directions. Capex is significantly less than LPBF (laser powder bed fusion), and part costs are dramatically less. Detail levels and accuracy can also be very high, but parts may sometimes distort and have issues with density. Time to part is longer than expected, and the footprint can also be considerable. Binder jet needs Easy Jet-like pricing models, whereby the build box is always moving and the machine is always printing. In these kinds of scenarios, binder jet produces incredible pricing that directly competes with many traditional technologies. In terms of machine design, machines multiple meters in size and huge format 3D printing (of small parts) with binder jet at the lowest part cost possible with Additive is potentially doable, but would require high investment levels.

My hopeful future scenario is a stark contrast to the more sensible view expressed by AI for manufacturing firm Uptool’s Co-Founder, Alex Huckstepp,

“After approximately 3 decades and ~$3B invested in commercializing AM Binder Jetting, no company has demonstrated they can build a profitable business around it. Perhaps Exone got closest before DM essentially killed it? HP and GE still have a hope, but this does not bode well for the future of AM Binder Jetting. I would say applications for plastics and ceramics have more, real demonstrated value and readiness but still struggle to compete with capabilities and economics of conventional molding (incl MIM) and machining.”

Ouch, but it’s very true what he’s saying here. For all its decades of development and billions invested, the technology has very little to show, and today’s practitioners are paying the price for promises made years ago by others.

Inkjet investment continues to rise as firms battle it out for inkjetting not only on paper but also on walls, dinner plates, and T-shirts. The vast investment in inkjet spanning decades has made this a formidable high-speed deposition technology. With higher laydown and higher viscosity technologies coming on the market, binder jet can build on the billions invested in inkjet to speed itself up, for free. More binders are possible now. Higher viscosity inkjet is bringing new types of jetting technologies to 3D printing as well.

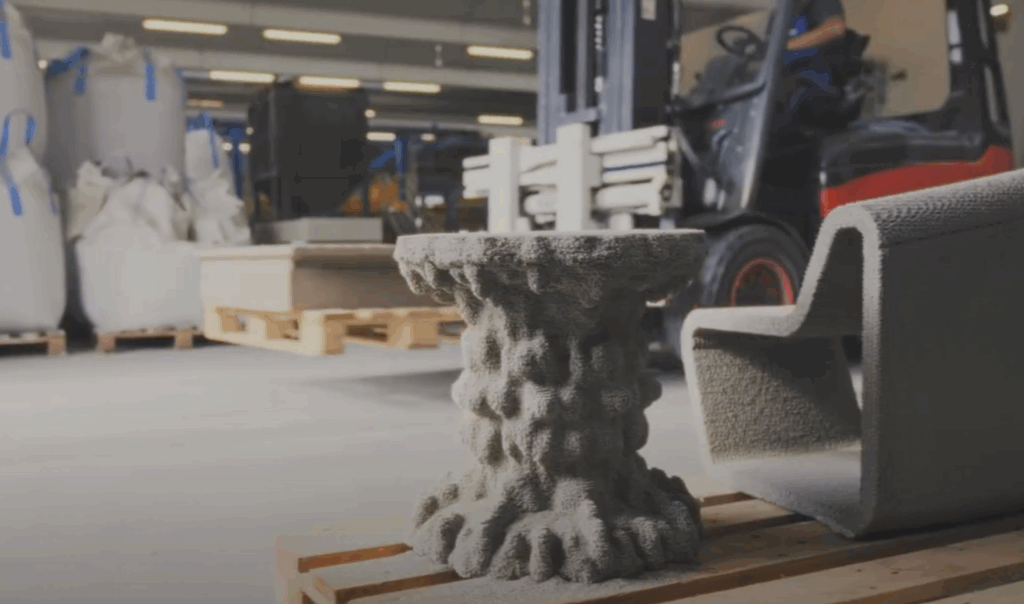

A new ecosystem is emerging, with companies using inkjet for construction, as Progress does with binder jet; for ceramics, as Durst spin-off D3D does with jetting; and others using jetting or inkjetting for viscous polymers. Binder jet is distinct from some of these technologies, but they could also lead to specific inkjet and ancillary technology development. Quantica is making its own print head while Novenda is raising money, and Align may use the technology as well. Better print head control from the likes of Meteor, more specific Xaar heads, better drop cams, and better simulation would go far to accelerate both material jetting and binder jet.

For part families that are squash ball-sized and require detail, low-cost binder jet is a very competitive technology. It could lose out to Slurry SLA when internal channels are paramount or when parts can be dumber, would lose to bound metal. But, high-volume series production for small complex metal parts looks to be the most attainable with binder jet right now.

Series Not Parts

The reason we can’t really discuss many real binder jet examples is fourfold. Firstly, as discussed, Desktop Metal sold everyone on this technology as a make-everything solution. At the same time, we were all chanting the high mix, low volume, and mass customization mantra. So everyone got lost in the woods for a decade, missing out on the millions of parts that could be made in series at low cost. We all spent a decade trying to be Porsche Individual and Bentley Mulliner and forgot all about the Camry.

Secondly, I know of several clients who have successfully 3D printed tens of thousands — and in some cases, hundreds of thousands — of parts over decades with binder jet. And you know what? They don’t want to talk about it. These little tchotchke parts are either too important or too mundane for them to care about getting press. There’s no GE bracket here, no champion shouting from the rooftops and showing people examples. This has always been a cure for many 3D printing companies and technologies, but is especially prevalent in binder jet.

Thirdly, expertise in binder jet on the design and process side has been too limited. There have been too few engineers, designers, and business people trained on the process; there are no free introductory trainings available, and it’s not really a focus of the 3D printing courses that we do have. Generally its always the War of Jenkins´ Ear of the 3D Printing curriculum, its always mentioned but never explained well. Finally, service bureaus offering binder jet directly to individual orders have been thin on the ground. No one has figured out the right stimulating pricing model whereby “you give me $1000 and I get you 100 chess pieces” works for everyone. These are the main factors keeping the industry small. A series of well-explained applications, a good course, and a service with a good business model are what could accelerate the technology today.

Where Will Binder Jet Win?

If you really want to make tough parts in austere environments, then 3D printing PAEK materials, Skuld, or Bound Metal are accessible options. For some parts, Spee3d could really work well, and for others, you have to graduate to the whole explody hoopla that is LPBF. For a lot of people, a kind of Laser Loving Greek Choir, LPBF is the 3D printing technology for grownups, and the rest of the stuff is machines that you give to your kid in the hope that they won’t study something utterly useless. Let’s all bow down to the Linde Gas totem pole and sing our laments. But, in diverting themselves towards making space propulsion, the LPBF crowd has its eyes on the skies. Their hundreds of large components are making the space race possible, but they are focusing their attention on high-ticket large part machines. For more quotidian parts at very high volume, binder jet, if packaged well (yes, that’s a binder jet bon mot, barely) and the right expectations are set, could provide the answer.

If you’re an energy company making technical spare parts available worldwide, if you’re a large industrial firm with many factories globally, if you are a defense or industrial group and have a lot of technical components in a library, if you have to make tens of thousands of triggers, tens of thousands of metal housings, tens of thousands of inserts, thousands of nozzles, thousands of guides, thousands of series parts then binder jet is probably the way to do this. Small, detailed, and relatively svelte parts are often best with binder jet. And in complex assemblies, machinery, and devices such as guns, machine tools, and electronics, the technology can play a role too.

There are, of course, alternatives in MIM that you can prototype or lead up to producing. Machining processes, casting, powder metallurgy, Slurry SLA, and MicroPrint exist as well. But, if you can run the machine continuously making things all the time, and then ramp up exigent parts, the economics for finer mechanical parts in runs from 500 to 50,000 are exceedingly good. But, if you run your machine in a kind of casual manufacturing way or without a stream of orders, the economics of binder jet are horrible.

For MRO (maintenance, repair, and operations), sustainment, and printing technical parts across many sites, binder jet is a leading possible solution. There are rumors of people trying to get binder jet parts qualified on aircraft. But that’s so old hat. In guns, grenades, drones, shells, fuses, charges, munitions generally, drive gears, switches, valves, brackets, pintles, housings, spacers, nuts, screws, other fasteners, connectors, nut sets, gear sets, bearings, and caps, binder jet is often the most accessible 3D printing technology.

The US has lost 1 million parts for the JSF. Lost, meaning they cannot find them. Building up and maintaining parts supply for small steel parts for the US military could be a multi-billion-dollar business for binder jet companies. Here, it is a question of deal shaping and technical ability. If you were able to qualify parts at scale and seek out similar parts through a combination of test printing and software, you could extend your library bit by bit. A lot of work would be straight-up reverse engineering parts and being the first to scan and digitize parts. Millions of parts don’t have a digital file. But that library would be very valuable to the government and suppliers. Even if you didn’t win the assignment, you could charge for them using your file. That same approach in setting up a low-cost qualification and selection system could help drive business with industrial partners as well. The library of parts idea seems to work well and could have a potential future for applications in binder jet technology. But, in what industries do we see binder jetting becoming more prevalent?

Small & Beautiful

Defense, energy, production lines, some capital goods, MRO, engines, industrial process automation equipment, sporting goods, chemical/pharma processing equipment and electronics are all promising markets for binder jet. Automotive components could be a good market. Now, this comes with the caveat that it would have to be at the right volume and car companies would have to help industrialize it further. Currently the pricing only works for certain families of parts and out of production parts. Realistically speaking an investment of hundreds of (well spent) millions would be needed to push parts costs down sufficiently and reduce errors for automotive and markets like electronics at part volumes of hundreds of thousands. I’ve only looked at this in a back of the envelope kind of way but am confident that $50 million or so just won´t cut it, if we look at the entire process that we´d have to jointly optimize in combination. I think that most would agree that if around $30 million would be spent on the process as a whole we´d make progress but the results wouldn´t be anything that would keep the die casting people awake at night. Familes of parts or very special parts could sway people but essentially we’re kind of stuck in the 1000 to maybe a 100,000 space for now. To me, the MIM guys look curious and bemused, not exactly terrified.

Binder Jetting Markets

The most promising markets currently for binder jet are mold inserts, luxury goods and medical devices. Luxury goods is a bright spot for binder jet and has been for many years. Across the largest luxury goods firms, awareness of binder jet is growing and across eyewear, leather goods and jewelry. The volumes, part sizes and detail is right and so many companies are playing with binder jet that we would expect growth here. Mold inserts, die casting inserts and other mold tools are a growth area. Mantle is doing well in the space and others are ordering parts for micro and other molding and across several markets. Medical devices has been particularly strong for binder jet across the decades but this kind of medical is different than the one we’re used to.

Lauralyn McDaniel of MFGGeek, has deep experience in manufacturing, approval processes and standards for medical 3D printing, she says that,

¨Medical applications are growing for almost every AM process. Metal binder jetting lags behind the laser sintering for devices in part due to the need to remove the binder and sinter after build. Laser sintering is also better suited for creating the complex porous structures that have driven the use of AM as a production method for orthopedic devices.¨

The things that sintering is super good at, binder jet can´t do. And generally medical companies are more knowledgeable about sintering. So further growth there will take time. But, if we look more towards the equipment and tools side of things there a lot of parts being made with binder jet. Here binder jet is winning at things that sintering sucks at. This is a high value market as well that values excellence and will reward continued service.

To me it is on these kinds of markets that we should focus. Gradual progress here will give us revenue while extending our capabilities. Binder jet has struggled to find product market fit, those perfect applications to drive growth and firms that champion the technology. There are however numerous bright spots emerging and the technology is growing across markets. It will take hard work and perseverance but volume is being unlocked.