Materialise has inked a collaboration agreement with Synera. Recently, Materialise has been working on an aerospace competence center in the Netherlands, partnered with companies to print aircraft interiors, and managed to increase revenues. Relative to the 3D printing software leader, Synera is much less known in our industry. Synera is an engineering automation platform where you can cobble together workflows of other companies’ apps to make repetitive tasks easier to do. Previously, the company has partnered with PanX, and the firm offers workflows for FEA (finite element analysis), light weighting, and more.

The two firms are going to hook up Magics SDK with Synera’s agent platform. The idea is that you can get an AI agent to handle workflows for you while you design parts. This couldn’t be any more timely if it were coated in Dubai chocolate. The SDK lets you open up and deploy Magics inside different tools, while the AI agents help teams take on repetitive tasks and run them more cheaply. There’s kind of a drag-and-drop agent path creation tool so that you can customize tasks tailored to your needs. Currently, the partnership will focus on automated file repair, support generation, and file editing tasks. Synera marketplace customers could also use the Magics functionality.

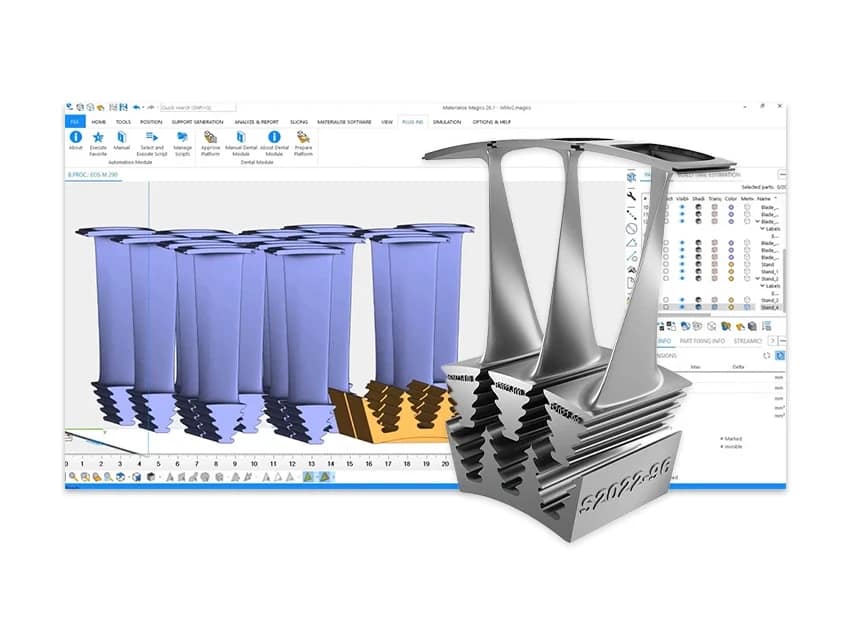

Materialise Magics SDK. Image courtesy of Materialise.

Synera Partner & Product Management Lead Andrew Sartorelli said,

“Our customers are already transforming their engineering operations with Synera by handing over repetitive work that all engineers dread to AI agents that autonomously optimize and prepare complex designs with less human intervention. Adding Materialise’s industry-leading build preparation capabilities enables our users to create comprehensive AM workflows that prevent build failures due to file preparation issues while standardizing and digitizing their processes.”

While Materialise Partnership Manager Gilles Claeys stated,

“With the Magics SDK, we’re opening decades of additive manufacturing expertise to help manufacturers automate and scale their workflows. The connection with Synera allows for a tighter integration between design and build preparation workflows, providing designers with immediate feedback on manufacturability and build optimization directly within one environment.”

Meanwhile, BMW’s Johannes Kolb thinks that,

“As an engineer working in additive manufacturing for years, performing file repairs repeatedly on hundreds of parts is one of the most time-consuming yet critical tasks in the workflow. Having Materialise’s robust AM capabilities integrated into Synera’s automation platform means we can now set up and adapt the build preparation to our own workflows to automatically identify and fix common issues. This not only saves hours of tedious manual work but also ensures consistent quality across all projects.”

I believe this is a great move for Synera, as it provides the company and its platform with access to the most powerful resurfacing algorithms in the business. The Materialise name is sure to drive customers and revenue toward the relatively unknown Synera platform. Synera is a fantastic strategic play as well. Imagine creating the Salesforce platform without needing to develop a highly popular software tool to drive adoption. Instead, the promise of integration will drive your platform, and the platform companies are the reason why people would sign up in the first place. It’s kind of like Tom Sawyer whitewashing the fence. Tom creates hype and interest around the task and ends up getting other boys to pay him to do it. In the same way, Synera is getting the industry to build its platform for them by making integration and automation look so appealing; others are eager to join in.

“Tom said to himself that it was not such a hollow world, after all. He had discovered a great law of human action, without knowing it – namely, that in order to make a man or a boy covet a thing, it is only necessary to make the thing difficult to attain. If he had been a great and wise philosopher, like the writer of this book, he would now have comprehended that Work consists of whatever a body is obliged to do, and that Play consists of whatever a body is not obliged to do. And this would help him to understand why constructing artificial flowers or performing on a tread-mill is work, while rolling ten-pins or climbing Mont Blanc is only amusement.”

PanX’s simulation and optimization for AM. Image courtesy of PanOptimization.

PanX and Materialise are providing the marketing draw, the tools, and the algorithms, while Synera focuses on accruing value to itself. All the value Synera builds goes to the platform, where its agents and workflows become the processes companies use all the time. At one point, the members of these workflows will become commoditized and replaceable.

“Nothing will change in your AM Repair Workflow, but we’re switching from Materialise to Netfabb.” I can only see Synera as a Trojan horse. From their point of view, it is audacious and could end up making the platform the dominant player in 3D printing software and beyond. By creating agents and a marketplace, whose costs can be spread across multiple workflows and tools, it will eventually become more powerful and efficient than alternatives. Then, flip to Autodesk and buy an island — you’ve built the next great platform without writing the core tools yourself. Any relationship where you don’t own the customer should be fraught with tension and worry; if it isn’t, you’ve just walked into a three-ring circus, and you’re more likely to be an elephant than the ring master.

For our industry, automated workflows uniting tools are definitely a plus. They could save us a ton of time. At the same time, however, AI is a black box whose functionality may change over time, which should surely limit the use of AI workflows and agents in Additive parts. After all, if it was a stable, unchanging workflow that was hard-coded, if you will, we can trust it. But if you’re going to make your agent cooler all the time, how do I know you’re not changing a No Support Zone at some point? How do you even know? We should therefore have a healthy skepticism about using AI every day without knowing how, when, and why the AI will be altered.

At the same time, this could lead to more casual Materialise use and introduce new people to their tools. It could also mean that people could opt for cheaper workflow tools and casual use instead of buying Magics licenses. And it can mean that Materialise’s own platform, CO-AM, could become less powerful. In the final analysis, a tool like Synera that ties together all AM tools into all possible workflows would save us an incredible amount of time. It is the ultimate solution that we all need. We’d have to place a lot of trust in that firm, however, because in fact we’d be giving them ownership over the future of 3D printing software. I’d be more comfortable sharing our collective roadmap with people who understand our industry, know our needs, and are wedded to our collective success. You know, someone like Materialise, for example.