Soft robotics for a long time was a lot of nice videos, papers, and very little in the way of useful technology. It was kind of an engineering Esperanto: a great idea with little in real world adoption and relevance. But, with the recent work by EPFL on elephant leg like structures with programable lattices, and now this news, it seems like soft robotics could finally be coming together at last. Soft robotics, could, for a certain class of goods, completely change how things are made. By making soft valves, pneumatics, and motors, soft things could, in a simpler way and using fewer materials, be less energy- and material-intensive alternatives to the electronic, chip, hard mechanical world out there. Instead of a Roomba with batteries, cameras, sensors, and chips, made out of hundreds of parts, the world could be so much simpler. Imagine a TPU blob that heats when your living room heats to give it motion, and rolls around collecting dust through static electricity. One part made with few materials could do a lot of what that super complex, super embodied energetic Roomba is doing.

The problem has always been that the research area has been too small to really collectively assemble a library of working functional parts that can be used by many to accelerate their work. A library of legs, lungs, valves, and actuators would really speed things up. There have also not been enough applications to get funders excited about soft robotics. And the things made with them often are not powerfully exciting enough to inspire more people to join the fray. Festo is essentially alone in inspiring people to move forward with this. Now, a team has come up with a soft actuator that, together with the elephant legs and the robot that walked off the printer, could really accelerate soft robotics development. To have devices that print in place, need no assembly, and have programmable lattices and actuators that work together would lead to families of devices that could make relevant, useful soft robotic devices.

In this research, published in Advanced Materials, a team from the Department of Materials Science and Engineering at Northwestern University has made strides towards a better actuator. Made through 3D printing elastomers, these mimic tendons and bones and can make human-sized, human power-like movement. Now this isn’t the first time that someone has explained their invention as being “artificial muscle.” But, in replicating the functions of a knee and ankle, the team has shown that they’re on a path to human-sized controllable power.

Northwestern’s assistant professor Ryan Truby said that,

“Robots are typically constructed from rigid materials and mechanisms that enable precise motion for specific tasks. But the real world is constantly changing and incredibly complex. Our goal is to build bioinspired robotic bodies that can be flexible, adaptable and embrace the uncertainty of the physical world. This includes bringing together not only practical artificial muscles, but also bone- and tendon- or ligament-like components to robotics. If we can do that, then robots won’t just become more resilient and adaptable. They will be able to harness the mechanics of softer materials to become more efficient.”

Researcher Taekyoung Kim said,

“It’s difficult to make robots without physical compliance smoothly respond or adapt to external changes and safely interact with humans. To make future robots move more naturally and safely in unstructured environments, we need to design them more like human bodies — with both hard skeletons and soft, muscle-like actuators….Even if you can make a material move like an artificial muscle, there are many other challenges like transmitting sufficient force with enough power. Interfacing them with rigid bone-like features presents even more problems.”

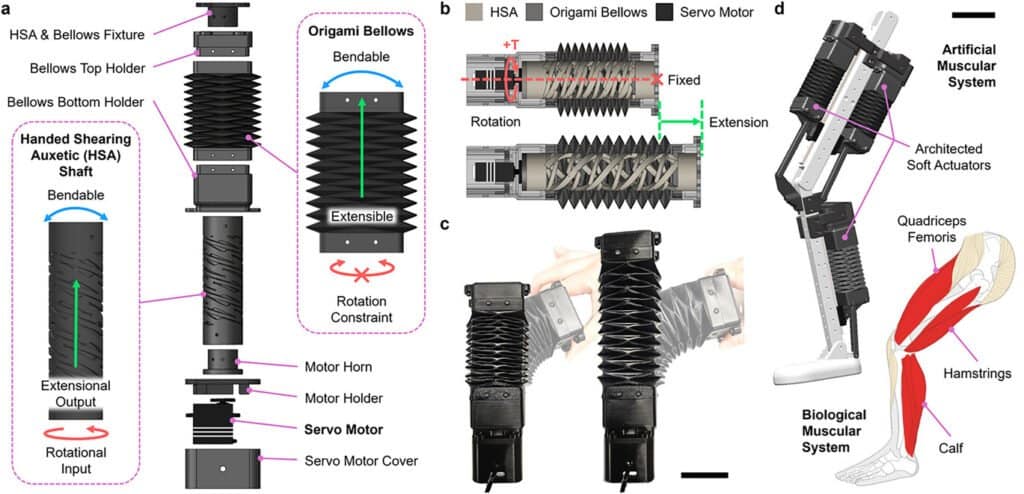

The actuator is made around a bellows-like structure with a shaft in it. The shaft is a handed shearing auxetic. The auxetic structure in this case gets thicker when stretched, and has been printed from SUNLU’s TPU on a Bambu X1 Carbon. The bellows is a Yoshimura origami structure, which consists of a cylinder with creases in the form of isosceles triangles that buckle in a repeatable way. This kind of structure allows for a rigid, thin walled cylinder to have significant repeatable elongation through buckling and compression. The actuator has some PLA 3D printed fixtures and is not completely a soft robot, as it includes a servo motor and load cell. There is also a microcontroller, linear rail, and an 8,200 mAh LiPo battery. The shaft and the part below are bendable, turn, and can extend.

There’s also a 3D printed sensor which stretches, changing the resistance and keeping track as to what extent the actuator has extended. This Kirigami Stretch Sensor has a specific pattern on it that comes from Japanese paper cutting. Whereas origami only uses folding, kirigami lets you make cuts in a sheet to, in this case, deform it in a repeatable way while letting it be conformal. The kirigami pattern is printed with Material Extrusion in TPU for non-conductive layers and a conductive TPU for the conductive ones; these are then sandwiched together. The researchers used TPU 95A Black from SUNLU and YOUSU Conductive TPU Black.

The team tested the unit with 3,600 bending cycles in a one hour time period. As well as pulling, the actuators can also push, and can handle loads 17 times greater than their weight. The team claims that their servo powered soft actuators “exhibit power and energy densities that are four orders of magnitude higher than those of other soft actuators.” This is promising work that shows a marriage of servos, electronics, and batteries with soft robotics. Maybe purists will scoff at this approach, but the results are interesting. The last twelve months or so have been great ones for soft robotics. More useful forms are starting to emerge. I hope that once we see people combine some of these innovations, we can really see some soft robotics inventions emerge that are not just promising, but useful.