A new paper shows some remarkable results for flexible bio-composites: continuous flax fiber-reinforced and bamboo charcoal composites were made through 3D printing. The new material shows a 1,571% increase in tensile strength and a 933% increase in energy absorption, and also managed to get a UL-94 V-1 rating. That makes the material bio-derived and potentially recyclable as well. If the research proves out, the material could be an excellent candidate for replacing CFRP materials in applications like sports and protective equipment.

The work was carried out by the UK´s National Composites Centre, lightweighting and multilateral design consultancy FAR, and Nottingham Trent University. Also working on the project is the energy absorption superpolymer company RHEON, which I’m guessing will commercialize this at some point. This material could have serious potential in high-performance clothing and high-end sports equipment. RHEON, with other materials, has commercialized through a Macron padel racket, Adizero Control x RHEON clothing, and Rapha padding. It seems intent on becoming a kind of Gore-Tex for energy absorption using metamaterials. I love RHEON and what they’re doing, and think that there could be a lot of opportunities across many consumer and industrial sectors in being the Gore-Tex for energy return, dampening, filtration, and more. RHEON has used innovative chemistry coupled with metal LPBF molds to make its metamaterials. But in this case, the very material has been compromised using additive.

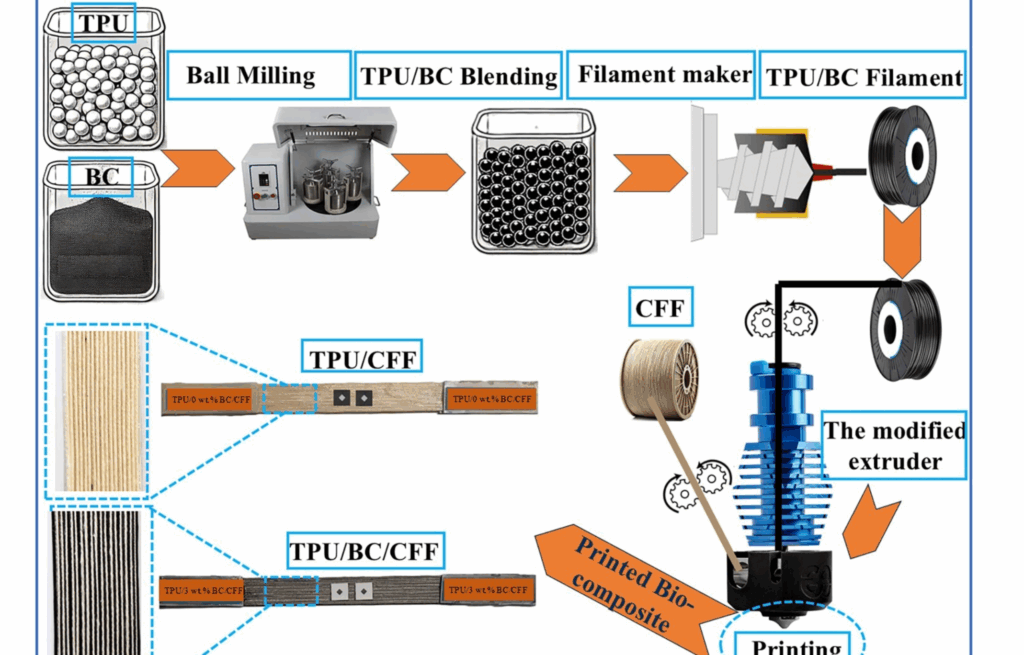

The bamboo charcoal and continuous flax fiber have been combined within a bio-based TPU. The matrix material is TPU, while the 25 µm bamboo charcoal powder improves flame retardancy and dampening. The materials were mixed with ball extrusion, blended, and then extruded into a filament on a 3DEVO filament maker. The flax fiber and the filament were then co-extruded on a Original Prusa MINI+. I love this approach, and indeed, I did something very similar around ten years ago with flax, hemp, and PLA. I know a lot of people who have tried similar things. There could also be a lot more combinations out there that would be possible. I love the idea of hemp continuous fiber printing as well. Years ago, I could not find any hemp fibers with the right tolerances and consistency; perhaps this is different now?

With 933% better energy absorption than TPU, this could be an exciting choice for energy dissipation, helmet liners, and pads. The environmentally-friendly aspect should also help sell this material to sporting goods firms, shoe makers, and other similar companies. I could really see them market this well as a kind of Eco Carbon Fiber alternative. Recycling it will still be rather annoying, but I guess mechanically recycling it crudely will lead to a great material for tiles and the like. Burning or melting it well could lead to a lot of other possible uses in the material’s second life. This kind of an innovation should be encouraged.

It’s also good to see that although the team uses a lot of testing equipment and clearly has deep knowledge of materials, the equipment used to make the material is fairly straightforward and obtainable. With a 3Devo machine, a ball extruder, and a Prusa, you too could make a similar material at your office or house as well. There are a lot of natural fibers out there which could fulfill a similar role. Think of hemp, sisal, abaca, and flax as fibers, and think of calcium carbonate, biochar, or other materials as a filler. The number of combinations is daunting, but through their careful arrangement, one could come up with alternatives to this material. I really think that metamaterials in general, and these kinds of bio-based composites specifically, are overlooked. A breakthrough, relatively inexpensive material could, for very specific applications, outperform many other materials. It will probably be much more expensive to 3D print structures than to use a foam, but it very well may be that the performance will be much greater with the 3D printed structure. At the same time, production of parts with these processes is inexpensive and doable because you can set up print farms of desktop machines. A material innovation could therefore be implemented and invented at home and printed in the tens of thousands of exemplars in 3D print farms at home. You could make the perfect material for skate board protective gear and then ship the parts from your house. The initial costs are doable and the scaling would be easy to do. A material with a real edge and low-cost production of end-use parts is now closer than ever, and it’s even eco-friendly, too.