Dutch industrial 3D printing company Parts on Demand, based in Utrecht, offers series production of end-use parts for customers from several sectors, from medical and machine tools to food and beverage, drones, and others. Parts on Demand uses selective laser sintering (SLS) technology, and operates eight industrial 3D printers. As its systems can handle quantities from one to 100,000 units, the company is busily pumping out between 20,000 and 30,000 components for customers each week. With roots in manufacturing and product development, Parts on Demand also has plenty of material expertise, and pairs this knowledge with optimized process parameters to print high-quality industrial parts.

At that level of series production, Parts on Demand needs to make sure that its parts are consistent and repeatable, and its process efficient. So the company turned to Rösler Group brand AM Solutions – 3D post-processing technology, for its automated post-processing equipment.

“We have significantly more orders to process today, and we are also facing challenges such as the sharp rise in energy costs. That’s why we need to make our processes more efficient,” explained Neil van Es, the Founder of Parts on Demand. “With the post-processing solutions from AM Solutions, we have reached a new level.”

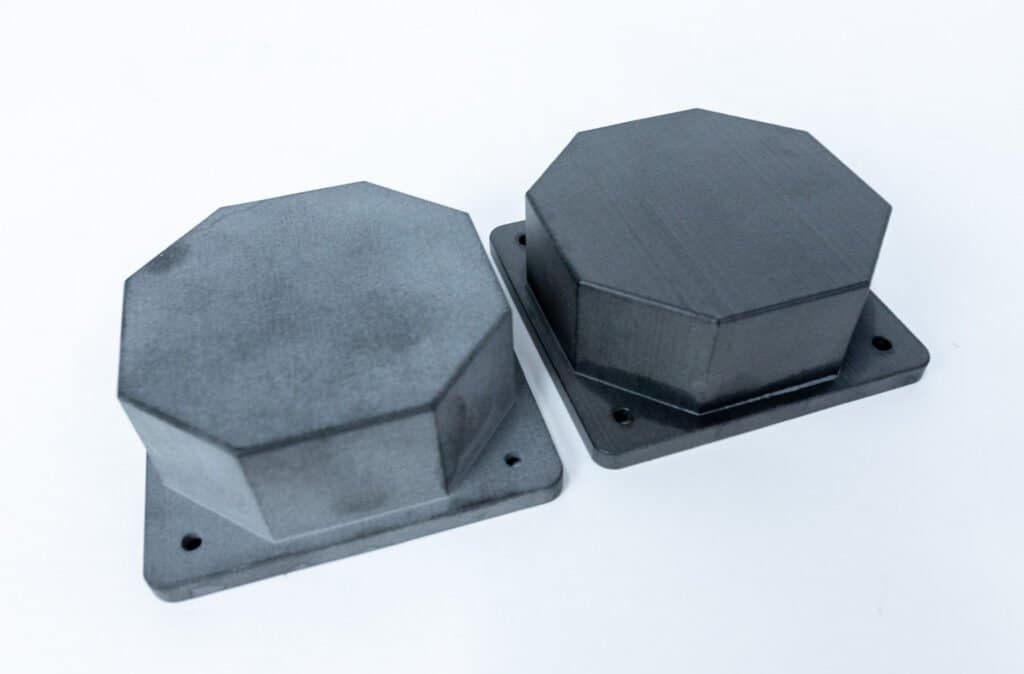

For comparison: On the left is an unprocessed component, and on the right is a component that has been processed in the S1. The result is significantly higher surface quality, which customers now automatically benefit from.

Specifically, Parts on Demand invested in two S1 shot blasting systems, one for dark parts and another for white ones. The nice thing about the S1, which has been used for 3D printed parts in consumer goods, automotive, materials research, and more, is that it’s a two-in-one solution. Previously, this kind of post-processing occurred in two separate systems, one of which was for cleaning, and the other for surface finishing. With the automated S1, both processes take place in one self-contained unit, which decreases operating time from 45 minutes to 15 minutes.

Once the parts are unpacked from the print bed, they go right into the S1 blasting system. A movable tumbling basket, designed for optimal part distribution, makes for easy loading and unloading. Constant rotation ensures consistent cleaning and finishing of printed parts, and operators don’t even need to manually remove components that don’t need surface finishing, as this step is now automated.

After unpacking, the parts printed in the powder bed pass directly through the S1 blasting system, which cleans and finishes the surface in just one step. This has reduced the time required from 45 to just 15 minutes.

Before they acquired their own S1 machines, Parts on Demand was offered the chance to put the system through its paces. At the AM Solutions Customer Experience Centre, the team extensively tested the S1 to see how it performed.

“We tried to push the system to its limits. No matter how unclean the parts were, they always came out clean. This extremely high performance, combined with the excellent support provided by our local branch in the Netherlands, was a key factor in our decision,” van Es said.

Another feature that sets the S1 apart is its use of polybeads for shot blasting, which help ensure better surface finish and are much more durable than their previous solution.

As van Es explained, “In the past, we used glass beads for de-powdering, but they had a short service life, so we ended up with a lot more waste. We now go from using one big pack per month to using one big pack every three months. This protects the environment and reduces another cost factor significantly.”

Neil van Es, the founder of Parts on Demand, is sure that, with the post-processing solutions from AM Solutions, they have reached a new level.

AM Solutions says that by investing in its S1 systems, Parts on Demand reports higher quality, 67% processing time savings, and 15% overall energy consumption reduction, thanks to lower compressed air demand.

Post-processing has long been referred to as the “dirty little secret” of the AM industry. According to the Additive Manufacturing Research report “Post-Processing for Additive Manufacturing: Market Analysis and Forecast,” authored by 3Degrees founder Mike Vasquez, post-processing is “a critical yet often overlooked part of the overall additive manufacturing workflow.” But the truth is, many of the pristine 3D printed parts that you see displayed at trade shows only look that nice because of post-processing. It’s not just about looks, either—these processes can help improve things like material performance and surface roughness.

But, the AM Research report also says that “new applications are within reach of the current cost and technical capabilities of additive manufacturing,” and maturing post-processing technologies play a big part in this. So there’s hope for us yet.

Images courtesy of AM Solutions