About a year ago, Markforged announced that it had enabled metal compatibility for its latest-generation composite printer, the FX10, thanks to a print engine adaptor optimized for two different kinds of stainless steel filament. The company recently released a video, produced in collaboration with luxury auto/supercar shop Graham Rahal Performance (GRP), that demonstrates how Markforged users are incorporating the FX10s into their operations for both composite and metal parts:

“If we can’t get it, we’ll make it,” Rob Sorum, a Fabrication Specialist at GRP asserts. “So that’s where I come in. When it was just me in the shop, I was the do-all — design, engineering, all aspects of fabrication, welding — it was all done by me.

“It’s a long process, and that is the downside of only having one person there: if you’re down for a month designing something else, and if another thing needs to be made, then it has to go on the back burner…if I could shave 20 hours off building a fixture — yeah, sign me up!

“What Markforged has done for us is basically like having that second hand. …I can go grab the part out of the printer, the FX10, and I don’t have to spend 20, 30, 40 hours sometimes building these fixtures.”

In addition to the fixtures, GRP has also used the FX10 for 316L stainless parts like the exhaust flanges for a Lamborghini Revuelto, a 1,000-horsepower hybrid supercar:

“We wanted to throw the gamut of all of our tools that we had at the [exhaust],” Sorum says. “…[W]hat makes it the most unique out of any other system out there are our Markforged 316L stainless steel flanges for the X pipe.”

Sorum goes on to point out that, in addition to being easier to weld than conventionally manufactured components, the printed part was also lighter, optimizing the performance of the Revuelto. As Sorum details in the video, the work he did with both the fixtures and the flanges is representative of how GRP has adopted the FX10 to streamline its workflow, in general: with one machine, the company has bolstered both its own processes as well as added to the catalog of parts it can offer to customers.

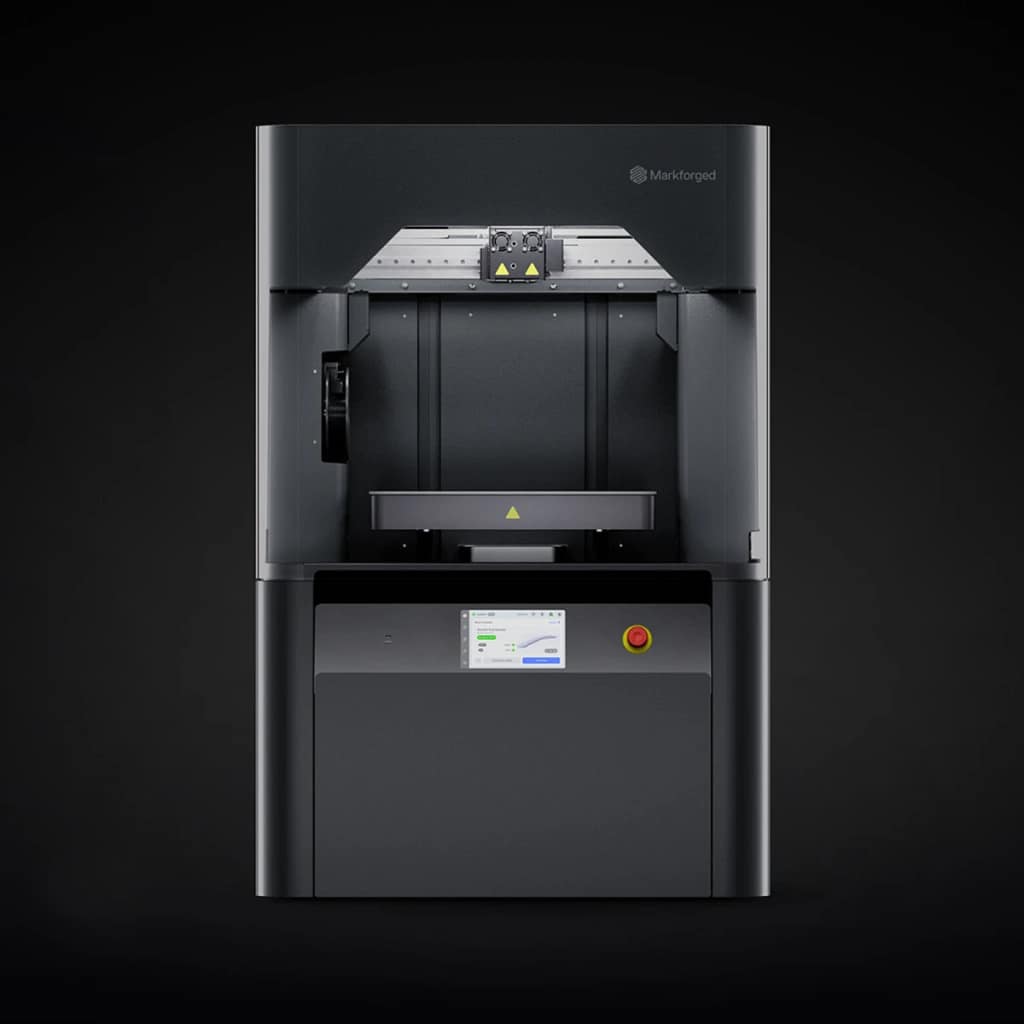

According to Markforged, the composite engine can be swapped out for the metal engine in just 15 minutes. Along with the interchangeability between metal and composite materials, the FX10 also features a much more compact and lighter design than its predecessor, the FX20, and was built to maximize the potential for automation.

All of these advantages seem to be on display in the GRP use-case video, and they’re all advantages that are highly relevant to what auto supply chains are facing in the tariffs era. Although, for the most part, it’s still too early to tell the precise extent to which tariffs will affect global supply chains, the auto sector is one exception: automakers have been scrambling all year to respond to the broad range of tariffs they’re now exposed to, and regionalization of supply chains is a major theme in that narrative.

The FX10. Image courtesy of Markforged.

Automation with advanced manufacturing, in turn, is a big part of this story of geographic reorganization, as suppliers are forced to do more with less to keep up with their shifting needs. The more that small and medium enterprises (SMEs) are brought into the equation, the more we can expect to see what’s happening at GRP become commonplace.

Beyond automotive, I think the FX10’s material interchangeability makes it a promising dual-use technology, especially given Markforged’s track record with military applications. If the Pentagon is serious about enlisting the help of commercial manufacturers to provide new surge capacity, then a machine that is equally capable of producing tooling and end-use parts, from both composites and stainless steel, would be well-suited to the task.

Like any company navigating an acquisition process, Markforged had to deal with many challenges unrelated to its core business operations over the course of the last year or so. But the company has also been focused on the right things for a long time, and it has a compelling ecosystem from end-to-end, so I think it’s still a brand that is very much worth paying attention to.

Featured image courtesy of Lamborghini