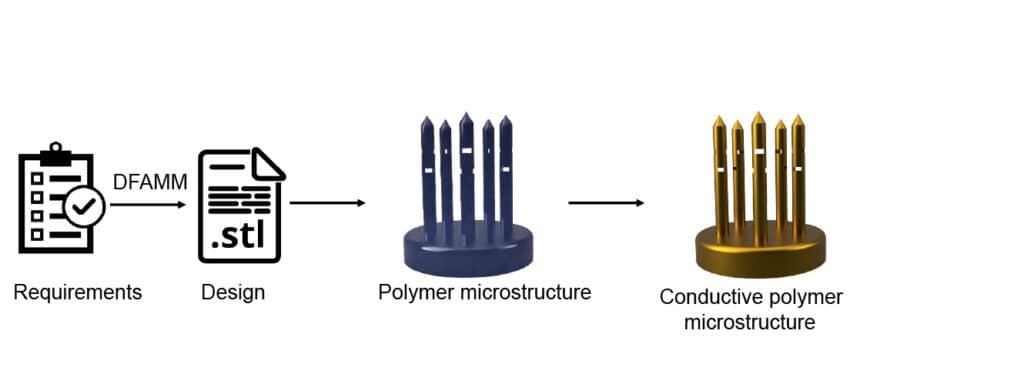

Horizon Microtechnologies has an innovative 3D printing process that combines DLP with dipping to make high tech components. Previously, the company showed that it can make electronics packaging, then developed antennas that are six times lighter than alternatives, picked up ESA funding, and opened an online shop to make buying antenna and other devices easier. The company uses a Boston Micro Fabrication (BMF3D) S240 DLP machine to make parts which are then dipped, coating them in silver, copper, and other metals.

Now, the company has passed outgassing tests as per the ECSS-Q-ST-70-02C standard. That particular standard is a screening test to determine the suitability of materials for use in space craft by the European Cooperation for Space Standardization, a standards body trying to unify standards for space agencies and commercial space companies in Europe.

“As described in the testing standard, the specimens were exposed to 125°C in a vacuum range of 10⁻⁶–10⁻⁷ mbar for 24 hours and weighed before and after the process as well as 24 h following the end of the tests. This serves to determine the amount of volatile content released and reabsorbed by the parts. In addition, the amount of material that condensed or otherwise collected on a test plate held at 25°C and located close to the samples was determined to see whether the tested materials could lead to contamination of neighbouring components. This is quantified as Total Mass Loss (TML), Recovered Mass Loss (RML), and Collected Volatile Condensable Material (CVCM), respectively. The results were:

- TML: 0.354%

- RML: 0.166%

- CVCM: 0.000%

“These numbers are well within the acceptance limits defined by ECSS-Q-ST-70-02C for materials intended for spacecraft (RML <1.00% and CVCM <0.10%).”

Horizon Microtechnologies CEO Andreas Frölich stated,

“This result is significant for Horizon as further validation that our combination of 3D printed material and coating delivers the level of reliability and material stability needed for applications where failure is not an option. Historically, coatings on 3D-printed parts have been viewed with scepticism due to challenges such as outgassing, delamination, and surface fragility. With this test, we’ve demonstrated that these barriers can be overcome.”

Outgassing, which is the release of gas in a vacuum (different from offgassing, which is release under normal conditions), is a great hurdle to space materials. One could easily imagine that users would be worried that the base 3D printed material may outgas, disrupting the dipped coating—in essence causing the part to buckle and destroy itself. This will therefore be a relief for Horizon, and will strengthen adoption.

The company hopes to go further and “validate our technology across all relevant stress domains, thermal, mechanical, and environmental. We are building a track record of success that we believe will fundamentally shift how engineers think about coating technologies for polymer AM parts.”

Next steps for the firm will be to complete radiation, vibration, and atomic oxygen tests. The company’s opportunities in making space components are considerable. Light weighting is extremely important in space, and coated polymer products can be significantly lighter than their metal counterparts. RF components generally are a huge application area as well. That sector is growing, and may allow for performance improvements in this arena. MEMS is also growing in additive, and this too could be an area where Horizon’s technology will play a role. Microfluidic devices are more nascent, but also a potential growth area.

On the whole, I really like what Horizon is doing here. They’ve developed a unique approach to conductive parts that has an evolving application arena. With dipping, they can still add lots of new functionality by adding different materials into the mix. Potentially, this technology could also very low-cost. But, without even ever discussing this, the company has also made it easy to order parts from them. That places Horizon in a good position for further growth. The firm is not spending a lot of money on marketing, or trying to change manufacturing forever. Instead, they are communicating very relevant information for companies that could buy from them. They’re communicating to space firms about their increased readiness in making parts for space. And one step at a time, they’re getting validation and approvals that make it more likely that this market could buy their products. A super smart approach that is humble, but very fitting to the moment. But, beyond the incremental improvements, there is real ambition here, and huge growth opportunities could occur if the company penetrates any one of the markets that it is targeting.