Headmade lets you take polymer laser powder bed fusion (LPBF) 3D printers and use them to print metal parts. Using what they call Cold Metal Fusion, a metal-doped polymer feedstock is printed on a slightly adapted version of a regular polymer LPBF machine.

In software, uniform shrinkage of around 14% is taken into account. After printing, green-state parts are water-jetted to remove the polymer powder, which acts as a support. These relatively stable green parts are then debound with a solvent and sintered in an oven. It’s a multistep process that requires some handling and workflow. But, by using older or relatively inexpensive equipment, it can produce metal parts at a relatively low cost per kilo.

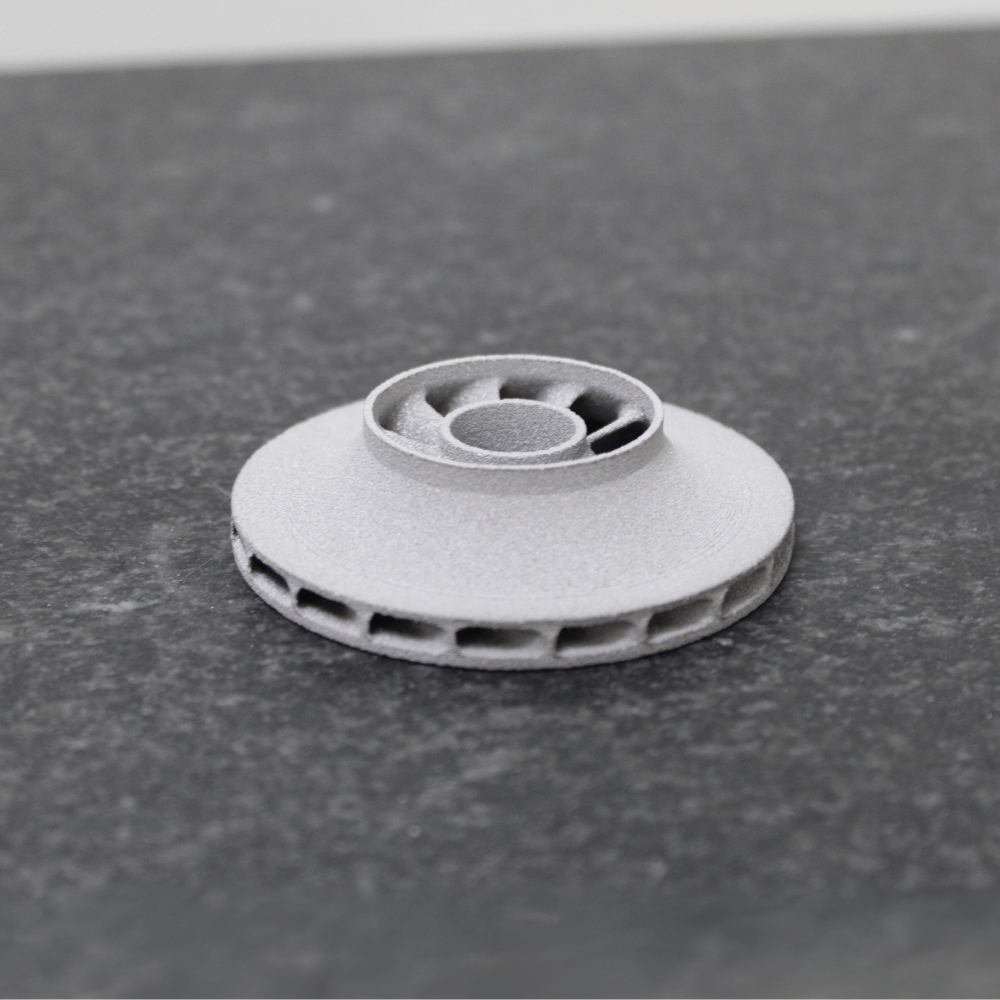

The resulting parts can be pretty detailed and could be used for some technical applications. They are dense, strong, and cheap. Cold Metal Fusion is a bit more expensive than bound metal filament printing, but delivers greater detail and definition. Compared to binder jetting, it’s less ideal for very small parts but can be less expensive, except at extremely high volumes, where binder jetting may win out for certain geometries. For other geometries, Cold Metal Fusion can produce parts that binder jetting simply cannot.

While it has less detail than binder jetting or metal LPBF, the cost savings are significant. LPBF still offers better internal control over microstructure and the ability to create lattices and other internal structures and textures. Slurry-based SLA has comparable economics but will tend to be better for detail, small parts, and internal channels.

The ideal Cold Metal Fusion part is a bicycle headtube, a metal building facade element, a complex metal filter housing, bike hubs, pressure nozzle flanges, industrial components the size of a shot glass that would require a lot of machining if made by other means. Better green part strength, lower capex, and lower part cost are the key advantages of Cold Metal Fusion. It can totally make sense for production runs starting from a few hundred units, at least until it can be bested by metal injection molding (MIM). By lowering unit economics and using existing equipment, Cold Metal Fusion is a real force for change and has the potential to disrupt metal AM economics in a meaningful way.

Cold Metal Fusion builds one-of-a-kind replacement parts.

Now, Headmade has demonstrated that the Formlabs Fuse1+ can be used to 3D print the intermediate forms of metal parts. The Fuse 1+ costs about $25,000, and already has a relatively large installed base of over 10,000 units. That means, eventually, users upgrading to newer models could repurpose their old Fuse systems to print metal parts.

This makes metal printing much more accessible. Please note that you would still need debinding equipment and a sintering oven. You don’t want to do this in your dorm room, and there are some important safety considerations to consider. Having said that, this is a great step forward in metal 3D printing affordability, especially concerning relatively inexpensive but detailed coffee cup-sized parts, where costs can now be significantly lowered.

Cold Metal Fusion builds one-of-a-kind replacement parts.

The work was carried out by 3D-WERK Black Forest GmbH. Based in the picturesque town of St. Georgen, the company runs Arburg, Farsoon, Formlabs, and PolyJet machines. The company specializes in dialing in new processes and helping clients set up and industrialize new equipment. For this project, they used Headmade’s Ti6Al4V feedstock and made minimal adjustments, essentially running it with standard PA12 settings.

This is a great step forward for the Formlabs community, which can now experiment with metal parts through occasional use of external debinding and sintering services. Alternatively, users could opt for a very inexpensive metal printing setup for under $60,000 and start producing parts in-house.

This is not the best solution for everything. 3D printing technologies are more like the different moves in Mortal Kombat; all work to a certain extent, but one is best for a given moment. But for some users, Cold Metal Fusion could be the perfect fit. It offers an inexpensive, scalable, and low-cost-per-part process that could enable industrial-scale production.

Some people could easily use the Fuse and Cold Metal Fusion to ship particular industrial end-use parts at scale. For individual entrepreneurs, this could be a way for them to commercialize an invention that was previously impossible to make at that price point. For people wanting to scale metal businesses, this could be a process with an unparalleled cost structure. For print farm owners, this could be a way for them to use old equipment to broach the metal market and start making more industrial components. Headmade is really onto something here, and I think that we will see products emerging around the Headmade and Fuse ecosystem in the years to come.

Images courtesy of Headmade