Despite all the assumptions that Western reshoring efforts would be bolstered by the tariff-centric trade war policies initiated by the second Trump administration, it’s still far too early to guess what the general outcome will be in the long run. Certain companies, including mega-caps like Apple, have announced their intentions to invest more in their domestic manufacturing operations, but it will likely take years before such actions lead to perceptible changes in the U.S. economy.

In the meantime, U.S. manufacturing activity contracted for a sixth straight month in August, with the economic uncertainty fueled by tariffs causing U.S. manufacturing stakeholders to adopt a decidedly cautious stance.

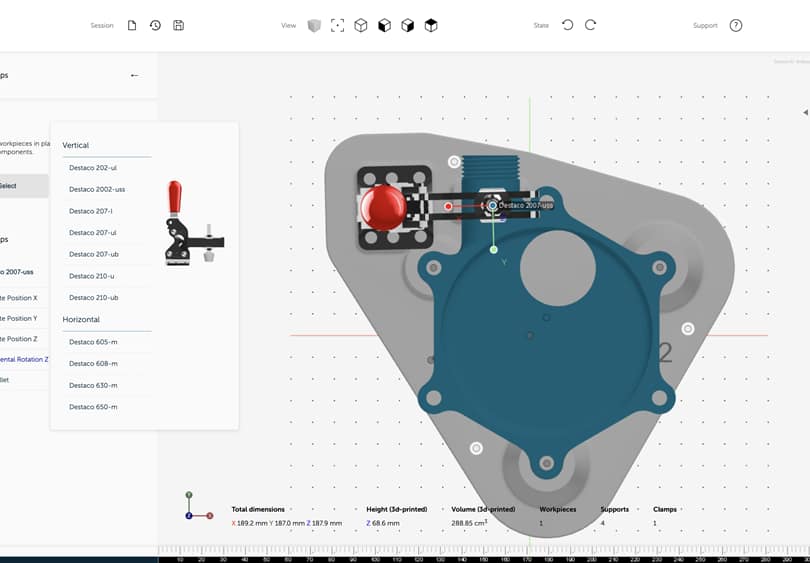

Digital fixture design with integrated clamping components.

All of this may seem to paint a pessimistic picture for supporters of reshoring, including the additive manufacturing (AM) industry. But the reality is, the longer that the prevailing uncertainty persists, the more likely it is that, ultimately, manufacturers will be compelled to start getting proactive about their plans for the future.

In this context, there are plenty of reasons for the AM industry and other reshoring proponents to be optimistic. The fact that there is no simple, conventional way to bring manufacturing supply chains back to the U.S. finally seems to be settling in. Those who understand the dynamics at play seem to know that they have to think long-term and outside-the-box, and be prepared to act strategically.

3D printed tooling for a curved composite part.

For the AM industry, specifically, the conditions of the current global business environment finally seem to be conducive for selling the best of what the technology has to offer: quantifiable methods for reducing costs and lead time, which, when gradually incorporated into a manufacturing enterprise’s workflow, can eventually evolve into an insurance policy for maintaining productivity, and even a way to completely change how parts are designed.

The latest white paper from AM Research, produced in partnership with AM industry pioneer Stratasys, details how AM companies can help their customers get a foothold in 3D printing with tooling applications. The white paper, entitled “3D Printed Tooling: A Generational Opportunity to Reshape Supply Chains”, can be downloaded for free here.

As the white paper outlines, verticals from across the manufacturing sector have for years leveraged AM to reduce the costs and lead times associated with applications including jigs and fixtures, molds, and a diverse range of other tools indispensable to a factory floor’s health. Stratasys is the perfect authority to inform this analysis. With well over a decade of providing tooling solutions to some of the world’s highest-value, highest-volume industries, there are few companies in the world as experienced in the realm of AM tooling applications.

An additively manufactured magnetic fixture for automotive assembly.

Manufacturers don’t have to choose between using 3D printing exclusively for prototyping and jumping into high-volume printing of end-use parts before they feel fully comfortable with the idea. 3D printing tooling expands the value of AM beyond R&D and puts manufacturers on the road to leveraging AM at scale. To hear that compelling story in full, download the white paper today.

Images courtesy of Stratasys