Today, Nano Dimension-owned Desktop Metal has filed for bankruptcy. Across a dozen funding rounds, the company raised over $816 million, had a SPAC, and was then acquired by Nano Dimension for $135 million on July 3, 2024. Now scarcely a year later, Nano is letting the firm go bankrupt, and says that this is a decision of Desktop’s independent board.

What Does this Mean for Nano Dimension?

Previously, Nano let Admatec and Formatec, DeepCube, and Fabrica go bankrupt as well. These firms were unceremoniously shut down without much in the way of shopping them, their IP, or their assets before bankruptcy. Likewise, Desktop Metal’s bankruptcy was long expected, but there seemed to be little activity in trying to sell the individual assets beforehand. I can only conclude that Nano wants to shed as much of its formerly acquisitive self before emerging as a lean butterfly that is less conglomerate and more a cash-rich focused startup. That is the most charitable thing I can say at this point. Another way to describe this process would be to see conserving cash as a priority, so much so that asset stripping is being overlooked, as asset shedding seems to be the main goal. I don’t really believe that Nano is getting the best deal for shareholders here, but they may see their long-term cash pile as being such an asset that they are willing to forgo sales of businesses or IP.

Nano’s takeover of Desktop Metal was never a happy one. Current management seemed uncomfortable with the deal. Parties danced around one another for quite a long time, and there was a bevy of lawyers issuing expensive threats. Was this the best way for Nano to unwind this unhappy marriage? It is definitely the quickest way.

What Does this Mean for Desktop Metal?

The company is a collection of assets, not well integrated. It’s more of a colloid than a structured, integrated business. It’s doubtful that someone would come along to save the entire thing. A limited solution for the US side of things could happen, but who would keep all of those diverse firms with very different offerings? There is also the matter of a legal action by a former law firm, and there could be more wrangling over the firm as a whole as well, due to fallout from the Nano-DM tussle over СIFUS approval and more. Because of this, a sale of the assets by a curator seems more likely.

What Does this Mean for the Constituent Firms of Desktop Metal?

ExOne as a whole could make an attractive target for a foundry supplier or company wanting to speed up foundry modernisation in the US, especially for defense. ANZU, who bid for Voxeljet, could perhaps buy it, or they could purchase the German arm independently. Sales cycles are long, but automotive and defense firms seem interested in digital casting alternatives as a way to speed up production.

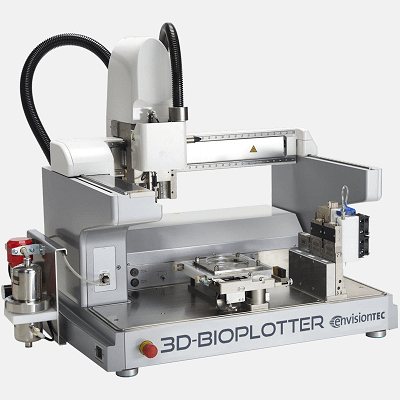

EnvisionTEC also has German and US components. The vat polymerisation market is very competitive, with a lot of low-cost entrants shaking up the business. Formlabs is also a fast-growing formidable competitor, and there are industrial firms such as Shanghai Kings and others making inroads as well. Perhaps a Chinese competitor would like to have the whole EnvisionTEC asset in order to produce in the US, circumventing tariffs and selling higher value products with a lot of Chinese sourced components. Similar to the Geely Volvo strategy, this kind of a trojan horse approach was very in vogue previously. But, with the US government being so unpredictable, Chinese investment in US firms may shy away at this moment. Other mid-sized SLA players are probably not big enough to acquire the firm, or would like to focus more on their own devices. EnvisionTEC actually has a lot of interesting IP in continuous production, new materials, and beyond vat polymerisation. These could perhaps be of interest to light engine firms, Formlabs, or other players in the industry like Align. A restart from Al Siblani could potentially be in the offing here as well.

AIDRO is a firm dealing with a very exciting application area. It’s a relatively small firm that has a real footprint in metal 3D printing for hydraulic components. Technological leadership in this field lies with Domin though. But I really think that new investment in AIDRO and a refocusing of its portfolio on more critical and higher end hydraulic solutions could make this a valuable application-driven firm.

Olaf Diegel’s 3D printed wood guitar, made using Desktop Metal’s Forust process. Image courtesy of Ric Fulop on Twitter.

Figur could also be valuable in the right arms; its digital sheet forming idea could quickly produce some parts very inexpensively. There are other startups working in the same area that seem to be doing well and it fits into the digitisation of the factory dreamscape. The Adaptive3D polyurethane resin business is very niche but it could well be a nice acquisition by a resin firm wanting to go into the additive business. The thiol chemistries are interesting and the application space is vast. Likewise, Adaptive subsidiary Syzygy Memory Plastics has interesting patents in this area also. AddLeap could in itself become a new startup if someone were to take their dynamic nozzle technology forward. Forust is something that, in the hands of the right entrepreneur, could become a steady manufacturer of consumer goods through binder jetting waste wood materials. Founders could also probably buy this back and have a good run with it.

What Does this Mean for binder jetting?

This now means that a few small firms, but mainly HP, have binder jetting on their shoulders going forward. It should mean less interest and less hype around the technology. Binder jetting for MRO, where you know what geometries you’ll print and want to do so all over the place in small series, is very exciting. The technology has been oversold however, and it will now have to find customers on the power of its ability, not just promises. Likewise, with the future of ExOne and Voxeljet in doubt, the technology generally is seeing a cloudy time indeed.

What Does this Mean for 3D Printing?

This is not great, and will sour investors even more on Stratasys and 3D Systems. We’re definitely in the doldrums now, in the eyes of the world. We’re unlikely to find a lot of new capital, and exits will be far and few between. There is right now a lot of growth in 3D printing. In applications, production, print farms, defense, prosthetics, orthopaedics, dental, space, and more, the industry is doing extremely well. But, the publicly traded companies and some industry stalwarts are not doing well. This will affect how we are perceived by the wider world. Industrial AI and other technologies will be of more interest to a lot of people. It is still perfectly possible to make a lot of money in additive, but it will be much harder, and you’ll have to earn it by making things.

What is the epitaph here?

Ford, Google, and New Enterprise Associates all invested in Desktop Metal’s fever dream for cheap metal parts. Over $800 million went in. From the outset we were aware that binder jet would make it difficult to dial in new parts and had limitations. I think that as an industry, we did not communicate this well enough. Desktop Metal’s initial machines worked very poorly, if at all. This was something we knew but didn’t publicise enough. Later machines were not able to turn the tide, and the company’s promises were never delivered upon by its own machines. Then, in the buying revenue phase, the company acquired firms that made revenue but were not necessarily growing. This meant that not only was buying revenue a finite strategy, but it would also not secure a future for the firm. It’s remarkable that Nano paid $135 million for the firm, and more remarkable still that Stratasys was offering $1.8 billion for it months prior.

After spending close to a billion dollars, Desktop Metal has precious little to show for it. Its own technology has never worked as advertised, and its financial performance has been terrible. Between 2020 and 2025, the firm had one year of revenues over $200 million. Over those years, the company had a negative net income of over one billion. One year, margins were at 16%, while most other years the firm had single digit margins; once, they were at negative 90%. Revenues have slipped 10% a year over the past years after cratering.

We should have been much more clear about the company’s over claims and boisterous behaviour. We should have been much more forthright in our skepticism about the gulf between their claims and performance. We all talked amongst ourselves, but didn’t consider it our duty to spread our doubts beyond our friends. That could have insulated us from this event. But, we remained far too silent publicly and now we reap the rewards of that. We’ve not given all we can, but some of us are still on the payroll.