With its Lithography-based Ceramic Manufacturing (LCM) technology, Lithoz has set the technological cornerstone for scaling ceramic additive manufacturing to industrial production for many key industries. These industries – ranging from aerospace and aviation, semiconductors, GreenTech to MedTech – are characterised by tightly regulated and closely monitored processes, strict qualification regimes, and highly time-sensitive logistic chains. Introducing a fundamentally new manufacturing system into such environments presents a major challenge, not only from a technological point of view. Moreover, both parties are faced with significant implementation challenges from a quality management and validation perspective. Selling first printers into these industries requires momentum and technological differentiation to convert a first touchdown into a long-lasting and reliable business partnership alongside traditional technologies. However, it is essential to keep up absolute discipline by respecting industry quality standards permanently, by ensuring precise technological repeatability, and by delivering worldwide customer support needed to establish both the process as a complementary full-fledged industrial ecosystem and the trust shown by the industry’s decision-makers.

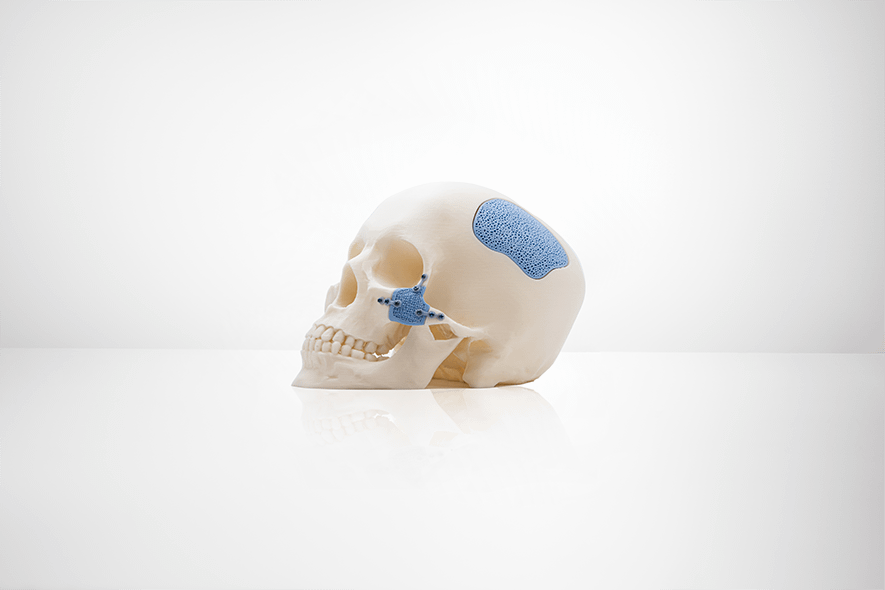

Bone Cranial and Zygomatic Implant. Image courtesy of Lithoz.

Lithoz has addressed this challenge by building not only a technology platform but an entire ecosystem around it. The fact that experienced yet agile service bureaus are much closer to those customers’ needs has smoothly closed the notorious growth chasm standing between startup and industrialization stages. Through its “Ceramic 3D Factory”, the company has established a global network of certified service providers, research facilities, and thermal process specialists that professionally manage direct connections to OEMs. This network plays a key role in transferring ceramic additive manufacturing from past research and prototyping phases into today’s industrial reality. It has been producing numerous real-world use cases at a serial production level and at increasing speed, all of which contribute significantly to industrial credibility. In sectors where adoption cycles are measured in years rather than months, long before in-housing new processes, they are first thoroughly tested by outsourced sample prototyping, followed by low-volume production batches of cost-insensitive parts, which are only then subsequently increased step by step to industrial production. Thus, the global “Ceramic 3D Factory” network is an indispensable intermediary offering fast and low-threshold access to LCM key technology to unlock efficiency potentials offered by merging high-performance ceramics with the freedom of design in AM.

One prominent example of LCM’s industrial adoption is Safran Aircraft Engines. In 2025, the French aerospace and defence group announced the acquisition of three Lithoz CeraFab System S65 printers to lay the foundation for their serial production of ceramic casting cores for next-generation aircraft engines. In aerospace, ceramic casting cores play a critical role in enabling complex internal cooling channels in turbine components, directly influencing engine efficiency, fuel consumption, and emissions. Using LCM, these cores can be manufactured with tight tolerances, thin walls, and intricate internal geometries that exceed the capabilities of conventionally produced cores. Safran’s investment reflects a broader industry trend: additive manufacturing is increasingly viewed as a strategic production technology that supports performance and efficiency improvements, supply chain resilience, and faster innovation cycles.

Safran’s decision marked a major milestone and can act as a blueprint for the entire ceramic additive manufacturing industry, as it demonstrated growing trust in this technology not only for prototyping, but for qualified, repeatable production for a key component in one of the world’s most demanding industries.

In a recent comment, Joris Peels aptly summarized the achievement’s symbolic significance: “Similar concerns are also at play in rocket engines, missiles, hypersonics, and other types of engines. This means that, with just this one process for this specific application, Lithoz could generate a lot more business. In the future, we can expect more firms to adopt Lithoz’s processes or explore using Slurry SLA for casting cores. A lot of people are probably reading this and thinking, “Well, whatever we’re doing, it can’t be harder than this.”

LithaCore ceramic casting cores. Image courtesy of Lithoz.

A further disclosed industrial use case in the semiconductor sector, where cost pressure reigns, and chemical resistance, thermal stability, and absolute precision are paramount, is a ceramic gas injector developed by SINTO Advanced Ceramics Europe (formerly Bosch Advanced Ceramics) using LCM technology. Manufactured from high-purity alumina, the additively produced injector integrates multiple functional elements into a single monolithic component. Internal flow-optimised structures, such as honeycomb geometries, enable precise gas distribution while reducing part count and assembly complexity. With dimensional tolerances in the ±0.1 mm range, delicate wall thicknesses of 0.2 mm across 62 outlet channels, and excellent resistance to aggressive process chemistries, the component produced in 2,000 units per year demonstrates how ceramic additive manufacturing can streamline supply chains and improve process stability in semiconductor manufacturing equipment. Again, this tiny yet significant innovation leap underlines the importance of the service bureau network as technology ambassadors, knowing the respective processes inside and out.

Beyond industrial hardware, Lithoz has also followed a long and well-considered roadmap in bringing medical applications to the market. With bone replacement as one of the focus areas for already more than a decade, the company has since been working closely with researchers, clinicians, and medical device manufacturers to translate ceramic 3D printing into clinical reality. A major milestone in this journey was the publication of the first-ever long-term clinical follow-up study on 3D-printed bioceramic implants produced using Lithoz’s LithaBone material, conducted together with customer KLS Martin. The study demonstrated a total success rate of over 92% across a five-year observation period, confirming excellent biocompatibility, mechanical stability, and bone regeneration performance. In Germany, more than 200 patients have already been successfully treated with this method.

These artificial bone-like implants, made from bioresorbable and bioactive ceramic materials, are designed to gradually integrate into the body while supporting natural bone growth. LCM enables patient-specific geometries and thus the speed of healing by controlled porosity and reproducible microstructures, all of which are critical for successful osseointegration. The medical field again exemplifies how ceramic additive manufacturing requires patience, rigorous validation, and close interdisciplinary collaboration over many years, and how it can deliver transformative benefits once it reaches maturity.

Johannes Homa. Image courtesy of Lithoz.

Across all these examples, one common denominator emerges: trust in a new technology is built incrementally, through performance in real applications. Research projects, long-term material studies, and close cooperation with customers and, above all, service partners acting as bridge builders have all played a pivotal role in supporting this development. Lithoz’s DNA revolves around delivering the highest possible quality in ceramic 3D printing while continuously pushing the limits of materials and process capabilities. This includes structured development programmes, advanced on-site training, and comprehensive customer support throughout the entire production workflow.

Johannes Homa, CEO of Lithoz, describes this approach as “scaling with trust.” “If you look at the ceramic 3D printing industry,” he explains, “the real growth challenge lies in moving from isolated successes to broad industrial adoption. With a growing number of validated use cases and serial production applications, we have reached a critical mass in several industries. This momentum is now naturally extending into previously untapped areas.”

Lithoz will participate in Additive Manufacturing Strategies (AMS) 2026, a three-day industry event taking place February 24–26 in New York City. The conference brings together industry leaders, policymakers, and innovators from across the global AM ecosystem. Johannes Homa, Co-founder and CEO of Lithoz GmbH, will speak during Session 1: Commercialization (9:40–11:00 AM), presenting a talk titled “Commercial Applications for Ceramic 3D Printing” at 10:50 AM. Registration is open via the AMS website.