Recent additive manufacturing experiments in microgravity have delivered promising results that could one day revolutionize the healthcare industry on Earth, from personalized wound care to the printing of viable organs for transplants. In 2024, Redwire Space bioprinted its first live human heart tissue on the International Space Station (ISS) and successfully returned the sample to Earth.

Space provides a unique environment for medical research because complex structures like organs can be grown without the need for support structures that would be required on Earth. Redwire’s 3D BioFabrication Facility (BFF) and others like it could one day eliminate the need for long waitlists and complicated matching processes for organ donations, as a suitable match could be printed on demand from an individual’s own cells.

Even before printing full organs for transplant becomes a reality, creating customized patches from a patient’s cells could reduce the risk of their body rejecting treatment for smaller repairs, such as replacing damaged heart tissue. Ken Savin, chief scientist at Redwire, sees a range of benefits for humanity from these smaller tissue prints.

“Printing tissues in space using our BFF facility on the ISS can create better tissue-like structures than has so far been possible using similar techniques on Earth, potentially using a patient’s own cells as a starting point,” he said. “Even before we get to the point of printing whole organs and tissue therapies, we can use the BFF to print small tissue constructs for models which could be used to test drug efficacy, possibly reducing the need for laboratory animals and speeding up new pharmaceutical therapies to market.”

Personalized in Situ Wound Treatment

Manufacturing human organs in space sounds like a concept straight from a science fiction novel, but there are some promising bioprinting applications in orbit that are surprisingly “low-tech.”

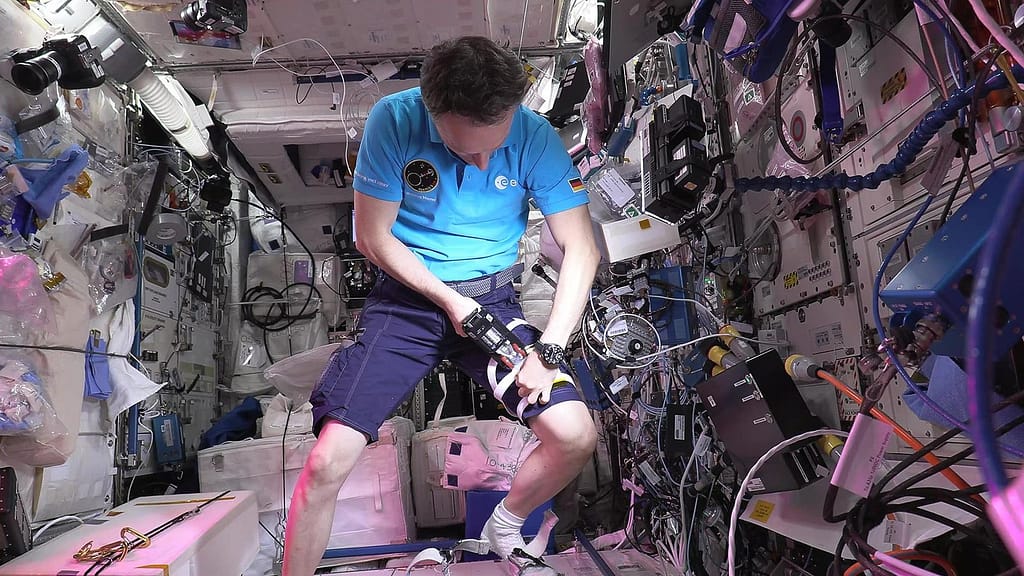

The German Bioprint FirstAid experiment, originally conducted by astronaut Matthias Maurer in 2022 with results published in 2024, tested a handheld device that could print a bio-ink “bandage” over a superficial wound.

Suspending an individual’s own skin cells in the gel would create a personalized wound treatment that promotes accelerated healing. This is especially beneficial to astronauts in microgravity, where natural healing processes like skin cell regeneration are slowed.

Matthias Maurer prints the bio-ink onto a foil sample on his leg during his time on the ISS. Image courtesy of NASA/ESA.

The device was designed by OHB System AG and is operated manually, not requiring a power source. It consists of two syringes, one filled with bio-ink and the other filled with a crosslinking solution. Wheels on either side of the applicator tip allow the user to smoothly apply the two gels over a wound. As the crosslinker absorbs down into the polymer, the mixture cures to a harder consistency, resulting in a solid layer similar to a bandage.

While the Bioprint FirstAid device is not a traditional 3D printer, it’s faster and more convenient to use than full-scale facilities. The bio-ink can set in about 10 minutes, and because it isn’t replicating tissues, it can be applied directly onto wounds rather than waiting for the structure to mature before application.

The simplicity of this device is part of its appeal — it’s accessible and applicable to the minor injuries that most commonly plague humans, both in space and on Earth.

The Future of Space Medicine

Beyond relatively simple experiments that have near-term applications, researchers are also utilizing space to explore medical advances that could revolutionize healthcare in the long term. Although it will take years before bioprinting technology is clinically tested and approved for medical treatments, there is still rapid progress being made.

In addition to printing the first live human heart tissue, Redwire printed the first human knee meniscus in space in 2023 and plans to print human blood vessels in a future mission.

Auxilium Biotechnologies’ AMP-1 printed a vascular network on the ISS, demonstrating the ability to 3D print blood vessels. Image courtesy of Auxilium Biotechnologies.

Auxilium Biotechnologies announced in February that its AMP-1 bioprinter had successfully printed implantable medical devices on the ISS.

This achievement is especially remarkable given its production efficiency: The printer simultaneously manufactured eight devices in two hours, including vasculature that demonstrates the ability to print blood vessels.

“AMP-1 is the most advanced 3D printing platform ever sent to space, enabling us to develop regenerative medicine treatments that can transform patient care,” said Auxilium CEO Jacob Koffler in a press release. “This facility not only demonstrates the feasibility of mass 3D printing production in space but also highlights the economic potential of space-based manufacturing.”

About the Author:

Zoe Hobbs is a senior data analyst at Space Foundation, a nonprofit organization founded in 1983 to advance the global space community through education, advocacy, and collaboration. The Foundation supports space innovation across industry, government, and academia — working to connect emerging technologies with real-world applications on and off Earth. To learn more about the Space Foundation’s mission and programs, visit www.SpaceFoundation.org. You can also follow their work on LinkedIn, X, Instagram, Facebook, and YouTube.