As we learned from our interview with Cedric Mallet, Bambu Lab had not considered the enterprise and manufacturing market when it launched its first 3D printer. Nonetheless, thousands of businesses worldwide have adopted the systems. From jigs, fixtures, brackets, and prototypes, Bambu machines have themselves become a fixture of offices and factory floors. Now, the company is launching an H2D Pro aimed at companies and professional users.

The dual nozzle printer will cost $3,799 and have a nozzle capable of reaching 350°C, and an active heated build chamber that can go up to 65°C. That should work well with PA, PPS, PPAs, and other engineering materials, as well as be handy in printing materials such as ABS and ASA. Lower temperature variants of PEEK will also be in range. That is a great range to have for many materials and applications, although we all want 420°C and 100°C so you can print pretty much all the materials, including PAEKs and Ultem.

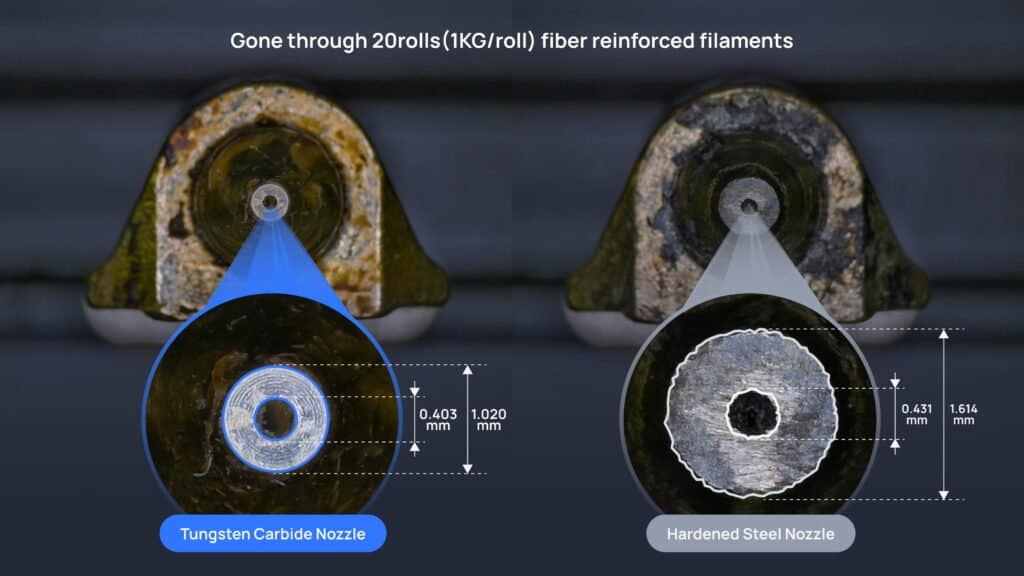

The company says that it has dual tungsten carbide nozzles to help with more abrasive, filled materials, and better nozzle cooling through a dedicated fan, which could help print larger parts well. Perhaps this may help the surface quality of larger parts, which affected early H2D models. The printers will have WPA2-Enterprise WiFi encryption, which is better than the WPA2 that we all use at home. The H2D Pro should have better airflow, reliability, and filtration. It includes the AMS PRO and AMS HT (separate High Temp material unit with active drying), and also comes with the Vision Encoder. This is a calibration tool that reportedly reduces motion accuracy drift. There’s also a comforting nice big red stop button, which is sure to give all the safety shoe, clipboard types warm fuzzy feelings. There is, thank goodness, no laser cutter. This is the printer I wanted to see from Bambu since they made the Carbon.

The company is also giving users support to develop and integrate their own software tools. Companies can therefore come up with their own fleet management software, or integrate the printers with existing systems. This will be a boon to universities and print farm managers. At the same time, it encourages people to write code for Bambu, and could lead to a secondary industry where software tools for Bambu printers become more prevalent.

Butenediol Vinyl Alcohol and PVA are supported, as well as a host of other materials. One listed is POM, and while this is a great material in terms of performance and cost, it can lead to risky fumes. If the H2D Pro performs well and is reliable, makes parts repeatably, and has good uptime, then this printer will do well. Print farm operators will probably stick to Minis and PSs for now, since they seem to love the value for money they get from these systems. For a university or in-office printer, this could be a great unit for many companies. Where this can really find a home is as a single printer for a department at a university or in an office. Whether it displaces other systems further afield, we do not know yet. Many companies would prefer to just get 4 to 6 PS1 systems for one of these. I’m a huge fan of redundancy and would like to just have a bank of PS1s with lots of materials loaded up.

But, if this prints polyamides well, a lot of companies and people in manufacturing could adopt this system. Truckloads of filament are currently being used to print all sorts of PA12 and PA12 CF components for industry. This market is a very attractive one. More so than a cost-conscious regular print farm, these kinds of enterprise print farmers are more able, and more likely, to invest in a larger system. To me, PEEK, Ultem, and other materials are now within reach, but this would probably need more of a redesign to work well.

Just the polyamides and PPA materials would do a lot of people a lot of good. Solid support material printing would also enable a lot of prototyping, and would see the H2D Pro displace a lot of UltiMakers in prototyping environments. The big rub has always been in Bambu’s support. Prusa Research’s documentation, tutorials, and support have always been far superior. UltiMaker´s customer support has always been excellent as well. Bambu has, for most of its short life, had bad or terrible to non-existent support. To deal with enterprise customers well, they will need to beef up on support and get a lot better at helping customers.

At the same time, we can see a lot of Prusa machines being engineered around their users. A lot of very practical stuff has been thoroughly thought out, and this has been absent from Bambu. UltimMaker, meanwhile, has a lot of features that save users time, like easily swappable nozzles. Bambu traditionally makes it tricky to do some very routine maintenance issues, and replacing or fixing nozzles is needlessly tedious and takes way too long. That needs to be fixed.

Bambu seems on a march to displace everyone in the Material Extrusion market. The company’s 7 models of printers now stretch from $199 to $3,700. From their first print to production, your kid and now your company can all use Bambu systems. By making all of its printers around the same core technology unit, it has even more amortization across the entire lineup than other companies. Parts sharing, but also bulking up on creating monitoring technologies that make printing better on all systems, mean that every printer contributes to and uses core Bambu technology. This is the firm’s strength. It is building a digital drop-on demand toolchain for more accurate, measured 3D printing, and every printer sold, and every spool run through, is helping to shore up their comparative advantage. If this printer works well and is a more reliable refinement of the H2D, then the Pro will help the company grow more in the enterprise market. A high-temperature printer and more sophisticated units seem like they’re only a matter of time. Even without increasing the form factor, a well-working Pro could displace Stratasys in a lot of offices. Bambu is continuing its relentless march to 3D printer dominance; what can competitors do to compete?

Images courtesy of Bambu Lab