Australian startup H3D has raised $5.8 million in Series A funding to expand its AI design software from hearing aids to dental devices. A spinoff born out of Swinburne University of Technology research, H3D’s technology is already used by manufacturers and labs to automatically design millions of custom-fit hearing aids, earphones, and hearing protection each year. Now, the company plans to bring the same automation to dental labs, where its software can process hundreds of cases in minutes instead of relying on slow, manual design work.

The investment round was led by Significant Ventures, with participation from Swinburne University and new investor Co:Act Capital.

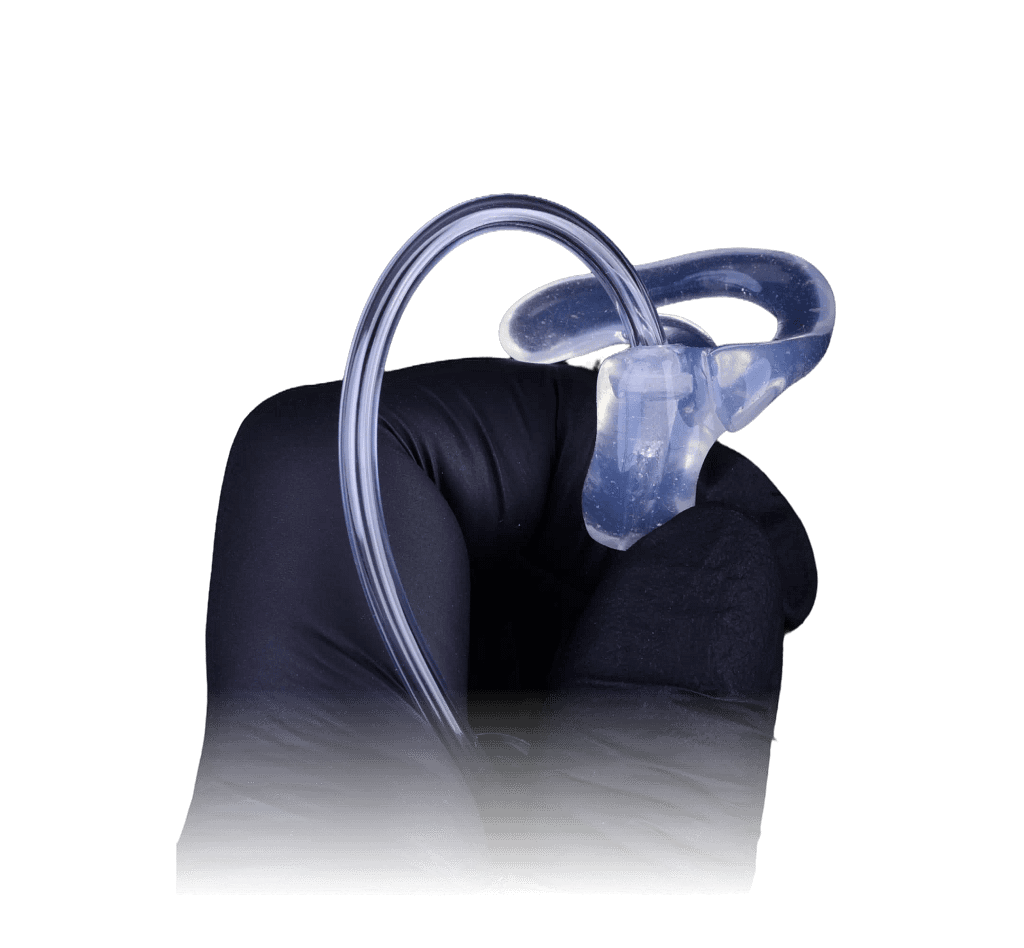

Behind-the-ear earmolds. Image courtesy of H3D.

H3D began as a research project in 2018 at Swinburne University, where co-founder and Chief Technology Officer (CTO) Dr. Philip Kinsella created an automated design system for hearing aid molds. Instead of relying on technicians to model each ear mold by hand, his software could instantly generate accurate, ready-to-manufacture designs.

Co-founder and CTO, Dr. Philip Kinsella. Image courtesy of H3D.

Today, H3D’s technology underpins the production of over one million hearing aid devices every year, including noise protection and in-ear monitors. This success is what convinced the team that they could solve a similar problem in the dental care industry.

Tackling bottlenecks in dental labs

H3D claims that dental labs still face slow, manual design bottlenecks because many still depend heavily on people and separate digital tools. Although there isn’t much global data on adoption, U.S. numbers give us a clue. In 2023, only about 17% of dentists in the U.S. had 3D printers in their practices. At the same time, about 80% of U.S. dental labs were using CAD/CAM as their main production method, but 3D printing was usually limited to models, guides, and dentures rather than full device workflows. All of this shows that while 3D printing is spreading in the dental industry, many labs around the world are probably still doing a lot of their work the traditional way.

So, dental manufacturing is still slow and labor-intensive. A technician using traditional CAD software might spend up to 30 minutes designing just one complex case. That means only one case can be handled at a time, and quality often varies depending on the designer’s skill.

H3D says its AI CAD platform “changes the equation.” It allows labs to batch process hundreds of cases in parallel within minutes, with a target acceptance rate of over 95%. The company says this automation will not only eliminate bottlenecks but also ensure consistent quality, helping labs meet rising global demand while lowering costs for patients.

H3D is pushing dental devices.

Expanding into hearing care

Even as it moves into dental applications, H3D is also strengthening its work in hearing care. The company recently launched a phone app that can take a precise 3D scan of the ear using just a smartphone camera. Using computer vision, AI, and AR, the app lets people skip the usual, often described as uncomfortable, ear mold process, where silicone material is pressed into the ear canal and left to harden, creating pressure and a blocked feeling. Instead, they can order custom-fit earphones or hearing protection from home.

H3D says its mission is to scale custom-fit products, which include hearing aids, dental devices, or even future wearables.

Smartphone scanning app.

For investors, the draw is using AI to make healthcare faster and more efficient.

“This funding marks a pivotal step in meeting the future vision of AI digital manufacturing,” said Iain McLeod, CEO of H3D. “By combining machine learning, advanced 3D algorithms, and real-time cloud processing into a seamless manufacturing solution, we can transform how patients receive dental and hearing care.”

Iain McLeod, CEO of H3D.

Michele Troni, Partner at Significant Ventures, added: “Having achieved commercial success in the hearing market, H3D is now ideally positioned to disrupt the larger dental industry. We’re proud to lead this expansion funding round.”

Kate Eriksson, Partner at Co:Act Capital, said her firm sees H3D as uniquely capable of delivering value in “two fast-growing global markets — hearing and dental.”

The new capital will allow H3D to expand its AI CAD platform to dental labs globally, strengthen its existing partnerships in the hearing industry, and continue developing tools like smartphone scanning to make custom-fit devices mainstream.

Images courtesy of H3D