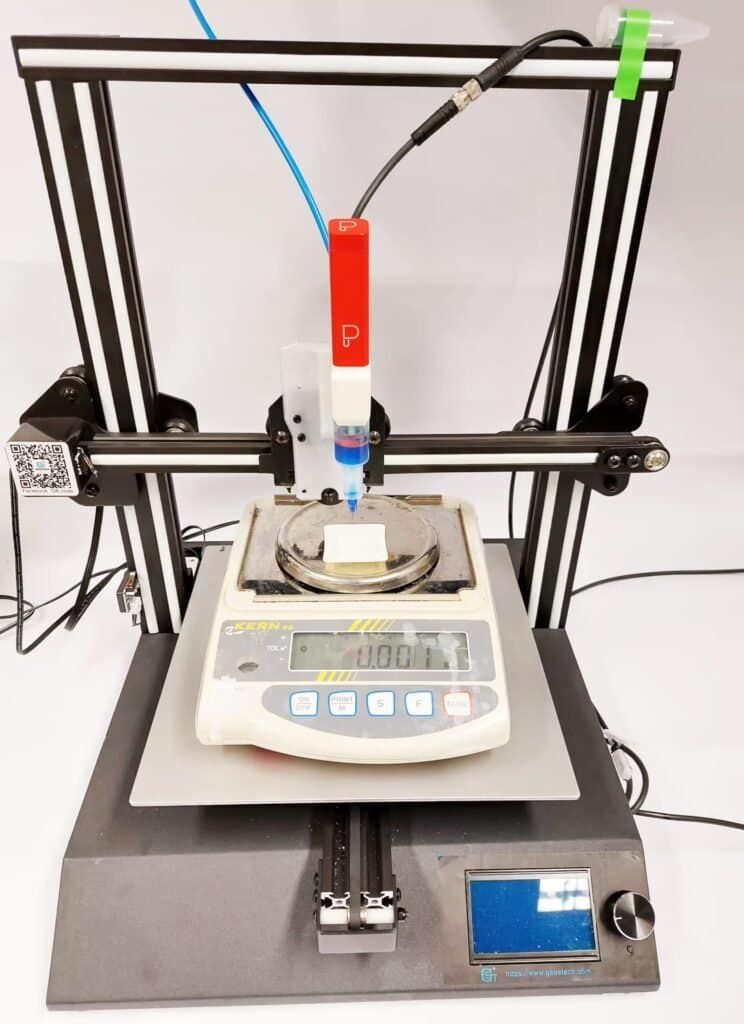

Puredyne is a spinoff of dosing nozzle manufacturer ViscoTec, which makes accurate endless piston nozzles for accurate dosing. ViscoTec nozzles power a lot of the silicone and other one and two-component extrusion 3D printers in use around the world. Puredyne is ViscoTec, but applied to bioprinting. Puredyne’s nozzles can print scaffolds, tissue, gelatin, cells, hydrogels, pastes, and more. Scientists can use the nozzles with bioprinters that they themselves make, with commercial ones that they’ve bought, or on desktop 3D printers that are then converted into bioprinters.

Now, the company has upped its game by adding pressure-sensing capabilities to its nozzles. That will improve process control and repeatability, and let users dispense more types of tissue and materials. In bioprinting, this improves the viability of biological materials and allows for more precise construction.

Puredyne hopes that in future, this will lead to “integrating machine learning algorithms and drives continuous improvement in printing performance. Users can leverage this technology to develop robust biomaterial databases, which can be crucial for optimizing future bioprinting applications. Another critical advantage: early detection of needle blockages, also known as nozzle clogging, allowing for proactive corrective measures.”

I’m very intrigued by the idea of users collectively improving performance through tracking and machine learning. This is very trendy, but if done well, would save many thousands of hours of work. For one, just think about how much time we spend dialing in details in 3D printing, and imagine a wider material set with more divergent temperatures, viscosities, and properties generally. In a second point, to have a database for all to use would compound these time savings for new market entrants. So much more could and would get done in bioprinting if not everyone has to spend weeks messing around with settings.

Puredyne thinks that its pressure monitoring approach is better than optical monitoring and lets the “sensor measures pressures between 0 and 10 bar relative pressure with an accuracy of ±2 %.” Aside from the company’s own nozzles, you could adapt the sensor to work with your syringe, or other extrusion process. It can connect to other devices via a Luer-Lock: a rubber stopper, threaded and tapered, seal connector that you may have seen in IV lines or when donating blood. Luer-Lock systems prevent air from entering the bloodstream during the administration of medicine, keep needles or tubes in place during procedures, let you mix in different medicines, and maintain the pressure and integrity of a system. Pressure monitoring lines in the ICU or during surgery already use both Leur-Locks and accurate pressure monitoring to check on continuous blood pressure through arterial lines. That is possibly where the Puredyne guys got the idea for this capability.

I’d love for people to look at this system more broadly and use it for other Material Extrusion applications, as well as Direct Ink Write or other technologies, like bioprinting. Pressure monitoring, to an industry extruding things with millions of devices, should be standard. Accurate pressure monitoring, plus understanding wall slip effects and pressure build-up, would help us all print better. Plus, typing findings to geometry and motor acceleration would allow us to optimize geometry far beyond what is being done today. By optimizing G-code for actually printing an individual part, we would get better results. I really hope that many people will look into this Puredyne pressure monitoring device. It seems like a very handy tool. More broadly, however, I really hope that people buy into Puredyne’s vision, because it is a credible path towards more coherent, accurate extrusion across many material families and extrusion technologies.