In this weekend’s 3D Printing News Briefs, we’re starting with metal coatings for polymer micro 3D printed parts. MELD is releasing its next generation of machines, Modix announced serial production of its new MAMA-1700 pellet 3D printer, and Kanfit acquired XJet’s Carmel 1400C and 5000X systems. Finally, a university student club won a national competition for its sustainable innovation project.

Horizon Establishes Metal Coating System for Polymer Micro AM Parts

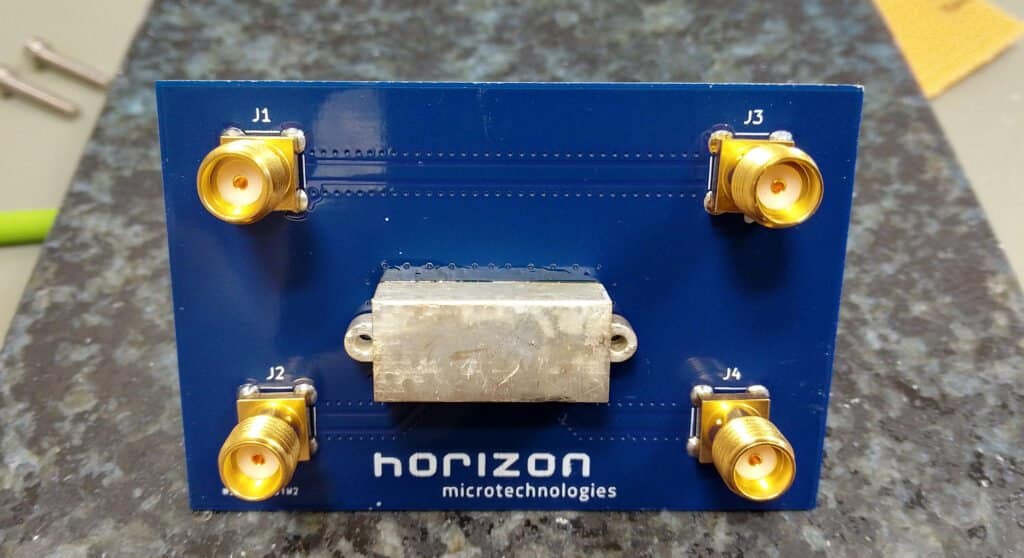

A Horizon-made surface mount signal filter component consisting of a 3D printed structural body with metallization on it soldered to a PCB.

Horizon Microtechnologies announced that it has established a material and coating system for micro AM that can successfully form a reliable solder joint between a metallized 3D printed polymer component and a standard PCB. This system, which has what the company calls “validated solderability,” uses standard processes from surface mount technology workflows. It proves that it’s possible to solder metallized polymer 3D printed parts to PCBs, which has important applications in standard electronics manufacturing workflows, including EMI/RFI shielding housings and surface mount devices that make use of 3D features, like custom connectors and RF signal filters. Additionally, this milestone shows interoperability between 3D printed metal-coated polymer parts and parts that, as Horizon writes, “leverage the many strengths of established, essentially 2D or layered electronics (and other) manufacturing workflows.” As CEO Andreas Frölich explained, while this may seem like a small step, “it’s actually a significant leap for the integration of AM parts into demanding electronics environments.”

“Our vision is to bridge the gap between polymer AM parts and industrial electronics processes. This latest result highlights more than just integration and durability, it validates the interfaceability of our coated parts with existing electronics workflows. That’s essential for delivering a complete solution, not just an exciting new option that comes with compromises,” said Frölich. “We’re only beginning to explore the potential of our technology in high-throughput environments like reflow soldering, and this result is an important step in that direction.”

MELD Releases New DragonForge Machine Series

Virginia-based MELD Manufacturing Corporation has announced the release of its next generation of machines. The DragonForge Series features equipment that was adapted specifically to achieve deposition of aerospace-grade alloys, such as titanium and high-strength aluminum, for large parts, but while still maintaining the original forging-like quality for which the company is known. With these processing enhancements, DragonForge machines are said to offer improved precision and performance with its AA7XXX alloys, like Aluminum 7075. The DragonForge series, available for MELD’s L3, K2, 3PO, and CD-14 printers, also has some new software features to improve user interaction and machine autonomy, as well as new simulation and monitoring capabilities. The most significant improvement is a digital twin capability, which helps operators optimize parameters, maximize print operations, and determine potential delays before printing even starts. MELD says that its new DragonForge can help solutions that require forging quality reach the market in just weeks, rather than months or even years.

As MELD’s CEO Nanci Hardwick said, “This equipment is truly next generation capability for rapid 3D printing of large aerospace parts.”

Modix Announces Serial Production of New MAMA-1700 Pellet 3D Printer

Israeli large-format 3D printer OEM Modix Modular Technologies announced that its flagship large-format pellet and filament 3D printer, the MAMA-1700, is now available and reaching customers around the world. The versatile printer (shown in the featured image) combines the precision of fused filament fabrication (FFF) with the high-throughput efficiency of fused granulate fabrication (FGF). It prints directly with plastic granules, which helps to reduce material costs while also opening access to a broader range of composite and polymer materials, including PLA, PETG, ABS, PP, Nylon, recycled plastics, and custom material blends. The MAMA-1700 has a 1,700 × 1,000 × 1,000 mm build volume, throughput up to 2.5 kg/hr with pellets and 0.5 kg/hr with filament, and interchangeable print heads, with a Griffin Ultra filament head for finely detailed prints and a pellet extruder for large-scale ones. Deliveries of the printer are already underway: the MAMA-1700 is being integrated into the Laboratory of Smart and Climate-Neutral Manufacturing Processes, Materials and Technologies Competence Center at Vilnius Gediminas Technical University (Vilnius Tech) in Lithuania, which marks an important turning point for innovation in the Baltic region.

“This production technology has almost no limits on the shape of the object being produced, so it can easily be used in architecture or interior design. For example, it is possible to create lighter and stronger structures, prototypes of wind turbine parts or components of unmanned aircraft. Also, innovative packaging or even wearable electronics,” said Associate Professor Dr. Arvydas Rimkus of Vilnius Tech, as reported by MadeinVilnius.

Kanfit Acquires XJet’s NanoParticle Jetting Solutions for Metal & Ceramic

Kanfit, which manufactures complex, precision metal and composite parts for high-end aerospace, medical, and industrial applications, is continuing its expansion into AM. The company has acquired two NanoParticle Jetting (NPJ) solutions from its fellow Israeli company XJet, the Carmel 5000X for 17-4PH stainless steel printing and the ceramic Carmel 1400C. Not only does this reinforce Kanfit’s already strong position in metal powder bed fusion (PBF) AM, but it also marks its entry into ceramic AM. The Carmel 5000X has twice the build volume of the already large Carmel 1400C, along with an advanced inkjet system with 100% ink recirculation, which minimizes waste. So both printers will help Kanfit deliver shorter lead times, improved performance, and more design freedom to its customers.

“With XJet’s metal and ceramic solutions, we can help our customers push the boundaries of innovation, producing highly complex components with unmatched precision and efficiency. XJet’s metal and ceramic inkjet solutions add another crucial piece to our comprehensive manufacturing capabilities. They enable us to offer unprecedented design freedom and production efficiency while maintaining the exacting quality standards our customers across all segments expect,” said Avi Danon, CEO at Kanfit.

UWA Student Club Project on Sustainability Won National Competition

This summer, a student club from the University of Western Australia, Enactus UWA, won the Early-Stage Award at the 2025 Enactus Australia National Competition for its project that pairs innovation and sustainability to reduce plastic waste and create social impact. The Polymer to Purpose project works to give recycled high-grade polymers from decommissioned subsea infrastructure a second life as 3D printing filament for applications like prosthetics and tiny homes. The student team conducted plenty of research and outreach, and worked with large-format 3D printer manufacturer Hyperion Systems and the TechWorks collaboration hub on their project, demonstrating how strong partnerships can help meet sustainable development goals. They’re now focused on actively transitioning their concept into the scaling and prototyping phase.

“While it may take time, all systems are go. We’re building strong foundations, gaining momentum and everything so far points towards making this vision a reality,” said Enactus UWA president Nhu-Y Nguyen-Tran, a Master of Marketing student. She also said that joining school clubs can be a great way to help students prepare for life after university.

“It can prepare you to work in an industry because you gain confidence, planning and presentation skills.”

This weekend in Bangkok, Thailand, the Enactus UWA team will represent Australia at the Enactus World Cup.